Integrating Ethernet into industrial automation improves your network’s speed, reliability, and flexibility, enabling seamless data exchange and real-time control. It supports advanced features like network segmentation, redundancy, and security measures such as encryption and firewalls. These enhancements help you reduce downtime, prevent cyber threats, and optimize operational efficiency. By choosing the right protocol standards and security practices, you can build a robust sensor-to-cloud system. Keep exploring to discover how these standards and strategies can transform your automation processes.

Key Takeaways

- Select industry-specific Ethernet protocols like EtherNet/IP, Profinet, or EtherCAT for seamless device interoperability.

- Implement network segmentation and VLANs to isolate control traffic and enhance security.

- Ensure robust security measures such as firewalls, encryption, and authentication to protect industrial networks.

- Design the network with redundancy and real-time features to improve reliability and minimize downtime.

- Adhere to protocol standards to facilitate compatibility, scalability, and easier troubleshooting in automation systems.

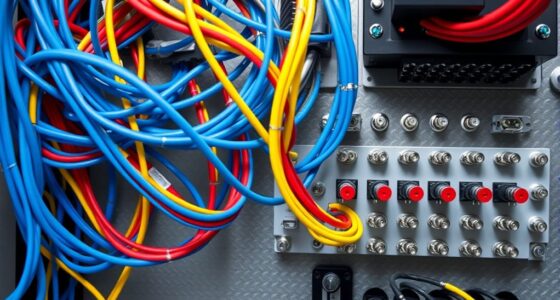

Ethernet has become the backbone of industrial automation networks due to its speed, reliability, and flexibility. As you integrate Ethernet into your automation systems, understanding how to ensure robust network security and adherence to protocol standards is crucial. Industrial environments are often targets for cyber threats, so safeguarding your network from unauthorized access and malicious attacks is paramount. You need to implement strong security measures, such as firewalls, encryption, and secure authentication protocols, to protect sensitive data and maintain operational integrity. Recognizing that Ethernet networks can be vulnerable if not properly secured, you should stay updated on best practices and emerging security technologies tailored for industrial settings.

Ethernet networks in industrial settings require strong security measures to prevent cyber threats and ensure operational integrity.

At the core of integrating Ethernet into industrial automation is selecting the right protocol standards. These standards define how devices communicate, guaranteeing interoperability and seamless data exchange across diverse equipment and vendors. Protocol standards like EtherNet/IP, Profinet, and EtherCAT are designed specifically for industrial applications, offering real-time capabilities and deterministic data transmission. By aligning your system with these standards, you facilitate compatibility, simplify maintenance, and enhance overall reliability. It’s essential to verify that all devices and network components conform to the chosen protocol standards to prevent communication issues and ensure smooth operation.

You also need to consider how protocol standards influence network architecture. For example, some standards support redundant pathways, which improve network resilience and minimize downtime. Others provide specialized features like priority tagging or real-time data handling, which are vital for critical control processes. When deploying Ethernet in your automation environment, pay attention to these features and configure your network accordingly to meet your operational needs. Properly implementing protocol standards not only helps in achieving optimal performance but also simplifies troubleshooting and future upgrades.

Furthermore, integrating Ethernet requires careful planning around network segmentation and management. Segregating control traffic from other network data can reduce congestion and improve security. Use VLANs and other segmentation techniques to isolate sensitive control systems, and ensure your network management tools can monitor traffic effectively. This proactive approach helps detect anomalies early and prevents potential security breaches or performance bottlenecks. Additionally, understanding the importance of standardization in protocol adoption can greatly enhance system compatibility and future scalability.

BV-Tech 8 Port PoE Switch with 1 Gigabit Uplink and Industrial DIN Rail – Power Over Ethernet Network Switch for IP Cameras, VoIP Phones, Wireless APs – IEEE802.3af/at, Wide Temperature Range

Seamless Power Distribution: Power and manage IP cameras, VoIP phones, and wireless access points with ease using the…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Does Ethernet Compare to Traditional Fieldbus Protocols?

Ethernet outperforms traditional fieldbus protocols by offering higher data rates and better protocol interoperability, making it more flexible for modern industrial automation. Unlike legacy protocols, Ethernet enables seamless integration with IT systems and supports scalable, real-time communication. You’ll find Ethernet simplifies network architecture, reduces costs, and improves device interoperability, making it a superior choice for future-proof industrial networks. Its widespread use also means better support and easier troubleshooting.

What Cybersecurity Measures Are Necessary for Ethernet-Based Automation Systems?

Imagine you’re in a sci-fi movie, but this time, protecting your Ethernet-based automation system is real. You need to implement robust cybersecurity measures like network encryption and strict access control to keep malicious actors at bay. Regularly update firmware, segment your network, and monitor traffic. These steps help guarantee your system remains secure, reliable, and resilient against cyber threats, much like a futuristic fortress guarding valuable data.

Can Ethernet Support Real-Time Control Requirements?

Yes, Ethernet can support real-time control requirements if you optimize for low network latency and guarantee protocol compatibility. By choosing real-time Ethernet protocols like EtherCAT or PROFINET, you reduce delays and improve synchronization across devices. You should also prioritize network traffic and implement Quality of Service (QoS) settings to meet strict timing needs, making Ethernet a reliable option for real-time industrial automation control.

What Are the Cost Implications of Ethernet Integration?

Like planting seeds in a well-tended garden, Ethernet integration requires careful cost analysis. You’ll face installation expenses for equipment and network setup, which can vary based on your system’s complexity. While initial investments might seem high, the long-term benefits—improved efficiency and scalability—often outweigh costs. Planning for these expenses guarantees smooth growth, transforming your automation system into a thriving, interconnected ecosystem.

How Scalable Is Ethernet for Large Industrial Networks?

Ethernet is highly scalable for large industrial networks, allowing you to expand device connectivity easily as your system grows. Its flexible architecture supports increased network size without significant performance drops, making it suitable for complex automation environments. You can add more devices or segments seamlessly, ensuring your network remains efficient and reliable. This scalability helps future-proof your industrial setup and minimizes costly rewiring or upgrades down the line.

Zyxel USGFLEX100H ZyWALL High Speed Cyber Security Firewall | 1-Year UTM Security Pack | VPN | Business Class | Up to 50 Users | Nebula Cloud Option | TAA Compliant

GOLD SECURITY PACK INCLUDED (1 YEAR): Anti-malware, sandboxing, IPS 1,500 Mbps, web filtering, DNS/IP/URL reputation, app patrol, AI…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

As you embrace Ethernet in industrial automation, you’re blending the simplicity of everyday networking with complex factory processes. It’s like switching from a handwritten note to a digital message—faster, clearer, more connected. While traditional methods hold their charm, Ethernet offers agility and scalability that transform your operations. So, while the past laid the groundwork, it’s the future—fast, reliable, integrated—that truly empowers your automation journey.

UGREEN Cat 8 Ethernet Cable 6FT, High Speed Braided 40Gbps 2000Mhz Network Cord Cat8 RJ45 Shielded Indoor Heavy Duty LAN Cables Compatible for Gaming PC PS5 Xbox Modem Router 6FT

40 Gbps 2000 Mhz High Speed: The Cat 8 Ethernet cable support max.40 Gbps data transfer and 2000…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Klein Tools VDV226-110 Ratcheting Modular Data Cable Crimper / Wire Stripper / Wire Cutter for RJ11/RJ12 Standard, RJ45 Pass-Thru Connectors

EFFICIENT INSTALLATION: Modular crimp-connector tool with Pass-Thru RJ45 plugs for voice and data applications, streamlining installation process

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.