Cable grounding and bonding are essential for safety and system performance. You should connect conductors securely using proper clamps or fittings, ensuring all conductive parts share the same electrical potential. Choose the correct grounding system, like TT, TN, or IT, based on your environment. Use high-quality materials like copper and follow safety standards. Proper grounding prevents shocks and equipment damage. To master these fundamentals, keep exploring the key techniques and regulations involved.

Key Takeaways

- Grounding connects electrical systems to earth to prevent shocks and equipment damage.

- Bonding ensures conductive parts are electrically connected, minimizing voltage differences.

- Proper materials like copper conductors and secure clamps improve conductivity and corrosion resistance.

- Following standards such as NEC, UL, and OSHA ensures compliance and safety in grounding practices.

- Regular inspection and maintenance are essential to confirm secure, corrosion-free connections and system integrity.

Bitiontry Copper Ground Rod Clamp, Great for 1/2”- 5/8” Grounding Rods (2, BCP58 (1/2''-5/8''))

Material: Copper ground rod clamp with galvanized bolt, standard duty. Maximum service and conductivity. to provide a solderless…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

The Importance of Proper Grounding and Bonding

Proper grounding and bonding are essential for electrical safety because they help prevent electrical shocks and reduce the risk of damage to equipment. When done correctly, they enhance electromagnetic compatibility by minimizing electrical noise and interference that can disrupt device operation. Effective grounding also provides a clear path for surge protection, helping to divert excess voltage caused by lightning strikes or power surges away from sensitive equipment. This reduces the likelihood of equipment failure and costly repairs. Proper grounding and bonding ensure that all parts of your electrical system are at the same potential, preventing dangerous voltage differences. In turn, this creates a safer environment while maintaining system reliability and performance. Prioritizing these measures is key to safeguarding both personnel and equipment from electrical hazards. Additionally, implementing performance cookies can help monitor system functionality and identify areas for further safety improvements. Ensuring compliance with electrical codes further enhances overall system safety and effectiveness. Regular inspections and adherence to grounding standards are also vital for ongoing safety and system integrity.

Brass Water Bonding Fitting for Swimming Pool 1" MPT – NEC Compliant for Inground Pools, Spas & Water Features – PB-2008 (PB-2008 / 08KIT-15 1.5" PVC Plumbing Kit)

NEC Compliant Water Bonding Fitting – Meets all National Electric Code (NEC 680.26) requirements for bonding pool water,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Types of Grounding Systems

There are several common types of grounding systems used in electrical installations, each serving different purposes and suited to specific environments. These include the TT, TN, and IT systems, each with unique bonding methods and configurations. For example, the TN system bonds the neutral directly to earth at the source, while the TT system isolates the earth connection from the supply. The IT system keeps the system’s connection to earth insulated or with high impedance. Additionally, understanding the nutritional benefits of various grounding techniques can help ensure safety and system reliability. Proper grounding practices can also prevent electrical shock hazards and equipment damage, contributing to overall system safety. Incorporating proper grounding methods can influence the electrical system’s stability and performance, ensuring reliable operation in diverse environments. Recognizing the importance of grounding system selection is crucial for optimizing safety and efficiency in electrical installations. Visualize these differences in the table below:

| System Type | Grounding Method | Typical Use Cases |

|---|---|---|

| TT | Earth rod | Rural areas, isolated sites |

| TN | Neutral bonding | Residential, commercial |

| IT | Insulated/High impedance | Hospitals, sensitive equipment |

Outlet Tester for Grounding Products – Test Receptacles & Sockets for Proper Wiring – Simple Tool for Electrical Assessment

✅ 𝗘𝗻𝘀𝘂𝗿𝗲 𝗦𝗮𝗳𝗲 𝗚𝗿𝗼𝘂𝗻𝗱𝗶𝗻𝗴: Quickly test if your outlet is properly grounded before using grounding sheets, mats, pillowcases,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

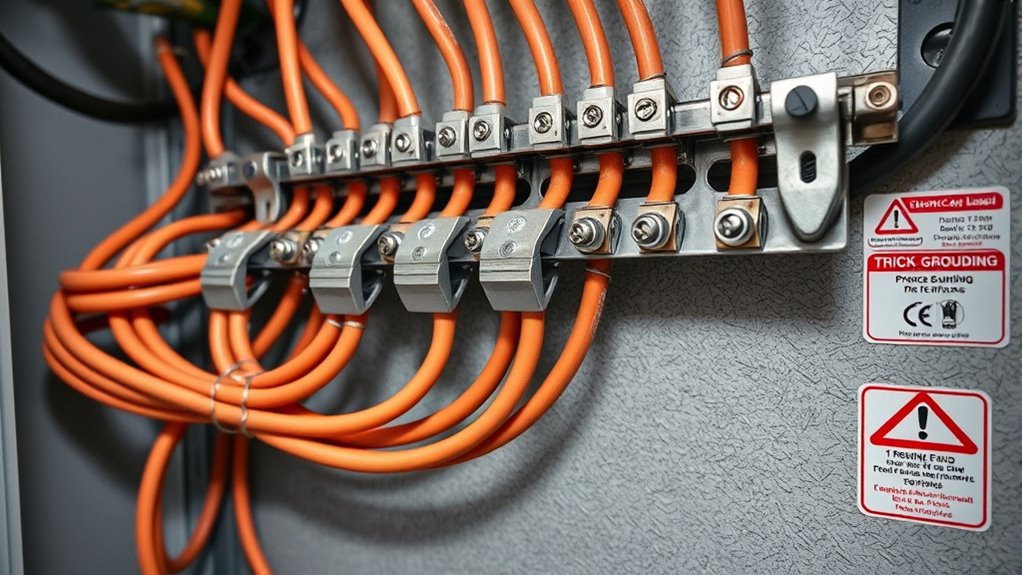

Common Bonding Methods and Techniques

To guarantee electrical safety and reliable operation, you need to understand the common bonding methods and techniques used in grounding systems. Bonding ensures all conductive parts are electrically connected, minimizing voltage differences. You’ll often use grounding clamps to attach bonding jumpers securely, creating continuous conductive paths. Proper selection of bonding jumpers and clamps is essential for durability and safety. Techniques include bolted connections, crimped fittings, and welded bonds, each suited for specific applications. Consistent and tight connections help prevent corrosion and maintain low resistance. Remember, effective bonding reduces the risk of electrical shock and equipment damage. Proper installation and maintenance are critical to ensure long-term safety and system reliability. Additionally, understanding grounding and bonding principles enhances overall electrical safety and system performance. Incorporating proper materials that resist corrosion is also vital for maintaining system integrity over time.

3Ft/90cm Long Flexible Bonding and Grounding Wire with Two Alligator Clips, Bare

Material and Specification: The bonding and grounding wire is made from a multi- strand aircraft cable with a…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Grounding Conductors and Materials

Selecting the right grounding conductors and materials is vital to guarantee effective and durable grounding systems. Copper conductors are preferred because they offer high conductivity, corrosion resistance, and flexibility, making installation easier and long-lasting. When choosing grounding materials, verify they meet your local electrical codes and standards. Copper grounding conductors are available in various sizes, so select one based on your system’s amperage and voltage requirements. Use proper connectors and clamps to secure the conductors tightly, preventing loose connections that could cause faults. Additionally, consider corrosion-resistant coatings or insulation, especially if your grounding system is exposed to moisture or harsh environments. Proper selection and installation of grounding materials ensure safety, reduce electrical noise, and improve system performance over time.

Grounding and Bonding in Residential Installations

Grounding and bonding are essential safety measures in residential electrical systems, guaranteeing that faults are safely directed to the ground and reducing the risk of electric shock. Proper grounding helps protect your home from lightning strikes by providing a path for lightning protection, minimizing damage. Bonding connects all metal parts, preventing dangerous voltage differences. Effective equipment grounding ensures that appliances and fixtures are safely grounded, reducing shock hazards. Remember, a solid grounding system also improves the overall performance of your electrical system.

- Ensures safe dissipation of electrical faults

- Provides a reliable path for lightning protection

- Prevents metal parts from becoming energized

- Reduces the risk of electric shock

- Enhances system stability and safety

Safety Standards and Regulatory Requirements

To guarantee your wiring is safe and compliant, you need to understand the key safety standards and regulations. The NEC grounding codes set the foundation, while UL certification standards verify product safety, and OSHA regulations protect workers during installation. Staying informed about these requirements helps you prevent hazards and meet legal obligations. Incorporating mindfulness practices into your safety protocols can also improve focus and awareness during installation, reducing errors and enhancing overall safety. Additionally, understanding self watering plant pots concepts can serve as an analogy for maintaining consistent and reliable safety practices in electrical work.

NEC Grounding Codes

Understanding the NEC grounding codes is essential to guarantee electrical safety and compliance. These codes set the standards for proper grounding and bonding practices, helping you avoid grounding myths and bonding myths that can compromise safety. Following the NEC ensures your installations meet legal requirements and reduce electrical hazards. Keep in mind:

- Grounding must create a low-resistance path to the earth

- Bonding connects metallic parts to prevent shock hazards

- The NEC specifies conductor sizes and types

- Proper grounding reduces electrical noise and surges

- Regular inspections ensure ongoing compliance

- The role of color temperature in projectors highlights the importance of accurate visual representation in safety signage and displays.

- Adhering to the grounding and bonding regulations is crucial for maintaining electrical safety and avoiding violations.

- Incorporating AI-driven solutions into inspection protocols can enhance the accuracy and efficiency of safety checks.

Additionally, understanding the appropriate conductor materials is vital for implementing effective grounding systems and ensuring durability.

UL Certification Standards

UL Certification Standards establish the safety and performance benchmarks that grounding and bonding products must meet before they reach the market. When your products are UL certified, you ensure they comply with strict safety and electrical safety requirements, reducing risks for users. UL certification involves rigorous testing and evaluation to verify durability, electrical safety, and proper functioning. This certification reassures you that your products meet industry standards and regulatory expectations. Additionally, meeting these standards can help prevent potential hazards and promote consumer confidence in your products. Incorporating AI-powered safety analytics can further enhance the monitoring and compliance processes for these products. Proper storage and handling, similar to storage guidelines for juice, are essential to maintain product integrity and safety throughout their lifecycle. Understanding quality assurance processes can also help ensure ongoing compliance and safety.

OSHA Safety Regulations

Have you ever wondered how workplace safety is enforced in electrical installations? OSHA safety regulations set strict standards to protect workers from electrical hazards. These regulations include proper grounding and bonding practices to prevent electrical shocks and fires. It’s important to understand grounding myths and bonding misconceptions that can lead to unsafe conditions. OSHA mandates regular inspections, proper equipment use, and employee training. Implementing remote work safety protocols can further enhance overall workplace safety. Proper grounding must meet specific resistance levels for safety, and bonding ensures continuous electrical paths. Regular testing verifies compliance with standards, and training reduces errors and misconceptions. Proper documentation is essential for inspections, and understanding the Glycolic Acid Benefits for Skin can be relevant when considering personal protective equipment for skin safety in certain environments. Additionally, understanding modern farmstead decor trends can inspire safer and more ergonomic workspace environments in agricultural or rural settings.

Troubleshooting Grounding and Bonding Issues

When troubleshooting grounding and bonding issues, start by verifying that all connections are secure and free of corrosion, as loose or damaged bonds can lead to electrical faults and safety hazards. Corrosion prevention is key to maintaining reliable connections, so inspect terminals and bonding conductors regularly. Look for signs of rust, oxidation, or discoloration that can increase electrical noise, disrupting proper system operation. If corrosion is present, clean the contacts thoroughly and replace any damaged components. Ensure that grounding paths are continuous and properly bonded to prevent voltage differentials that cause electrical noise. Using proper tools, measure resistance levels to confirm good connections. Addressing these issues promptly helps maintain system safety, reduces electrical noise, and prevents potential faults caused by compromised bonds.

Best Practices for Effective Grounding and Bonding

To guarantee your grounding and bonding systems work effectively, you need to follow proper techniques and maintain system integrity. Using correct grounding methods minimizes interference and safety hazards. Regularly inspecting and testing your bonding connections helps keep the system reliable and compliant.

Proper Grounding Techniques

Are you following the best practices for grounding and bonding to guarantee safety and reliability? Proper grounding techniques involve establishing a solid connection between your system and a grounding electrode, ensuring effective dissipation of fault currents. Use a bonding jumper to connect metallic parts, creating a continuous conductive path. Properly sized and securely installed grounding electrodes are essential. Additionally, keep grounding conductors free of corrosion and damage. Correct installation methods help prevent electrical noise, equipment damage, and safety hazards. Remember these key points:

- Use the correct grounding electrode material and size

- Ensure tight connections with appropriate hardware

- Maintain a low-resistance path to earth

- Verify bonding jumper integrity and placement

- Follow local electrical codes and standards

Implementing these techniques enhances system safety, performance, and longevity.

Bonding System Integrity

Maintaining the integrity of your bonding system is essential for ensuring a safe and reliable electrical setup. To prevent issues like corrosion, regularly inspect and clean bonding connections, especially in humid or corrosive environments. Using corrosion-resistant materials or coatings helps protect components over time. A sound bonding system minimizes electrical noise, which can interfere with sensitive equipment and cause false readings. Ensure all connections are tight and free of oxidation, as loose or corroded bonds weaken the system’s effectiveness. Properly grounded and bonded systems reduce the risk of voltage differences and static buildup. By following these best practices, you enhance system durability, prevent corrosion-related failures, and sustain consistent electrical performance, keeping your installation safe and efficient.

Frequently Asked Questions

How Do Grounding and Bonding Affect Electromagnetic Interference?

Grounding and bonding improve electromagnetic compatibility by directing unwanted electrical noise away from sensitive equipment, which helps reduce electromagnetic interference. When you properly ground and bond cables, you create a low-resistance path for interference currents, minimizing noise that can disrupt signals. This setup ensures your system maintains stability, enhances performance, and keeps electromagnetic interference at bay, leading to better noise reduction and reliable operation of your electrical and communication systems.

Can Improper Grounding Cause Equipment Damage?

Yes, improper grounding can cause equipment failure and safety hazards. When grounding isn’t done correctly, electrical faults can lead to voltage surges or stray currents that damage sensitive equipment. You might also face increased risks of electric shock or fire. Ensuring proper grounding and bonding is essential to protect your systems, prevent equipment failure, and maintain a safe environment. Always follow recommended procedures for effective grounding.

What Are the Environmental Impacts on Grounding Systems?

Like a fragile leaf in a storm, your grounding system faces environmental challenges. Soil conductivity fluctuates with moisture and temperature, affecting grounding effectiveness. Harsh conditions can lead to corrosion, weakening connections and risking safety. To protect your system, guarantee proper corrosion protection measures and monitor soil conditions regularly. This way, you maintain a reliable grounding system, safeguarding equipment and ensuring safety despite environmental impacts.

How Often Should Grounding Systems Be Inspected or Maintained?

You should inspect and maintain your grounding system at least annually, performing grounding system testing and bonding connection checks regularly. These inspections verify your system remains effective, especially after severe weather or changes to your setup. Look for corrosion, loose connections, or damage. Consistent testing and bond checks help prevent electrical faults, protect equipment, and ensure safety, keeping your grounding system reliable and compliant with standards.

Are There Specific Grounding Requirements for Outdoor or Wet Locations?

Think of grounding materials as sturdy roots that hold your electrical system steady in outdoor or wet locations. You need to follow specific requirements, such as using corrosion-resistant grounding materials and reliable bonding techniques, to prevent electrical faults. These measures guarantee your system stays protected against moisture and weather, like a tree resilient against storms. Proper grounding keeps your setup safe, durable, and compliant with electrical codes, especially in challenging environments.

Conclusion

Proper grounding and bonding are vital for safety and system reliability. Did you know that improper grounding can cause electrical shocks or fires in up to 20% of residential accidents? By understanding and applying the right techniques, materials, and standards, you can guarantee your electrical system remains safe and effective. Stay vigilant, follow best practices, and regularly troubleshoot to prevent costly issues and protect your home and loved ones.