When choosing between punch-down and crimping techniques, consider your specific needs. Punch-down is ideal for organized, flexible cabling in structured settings like patch panels, offering neatness and ease of future adjustments. Crimping delivers durable, strong connections suitable for outdoor, industrial, or high-stress environments. Your choice affects installation speed and connection reliability. To guarantee the best results for your project, understanding the differences and when to use each method is key—exploring further can help you make an informed decision.

Key Takeaways

- Punch-down is ideal for structured cabling, providing a neat, low-profile connection suitable for patch panels and organized wiring.

- Crimping offers a quick, durable, and strong connection, often used in outdoor, industrial, or high-stress environments.

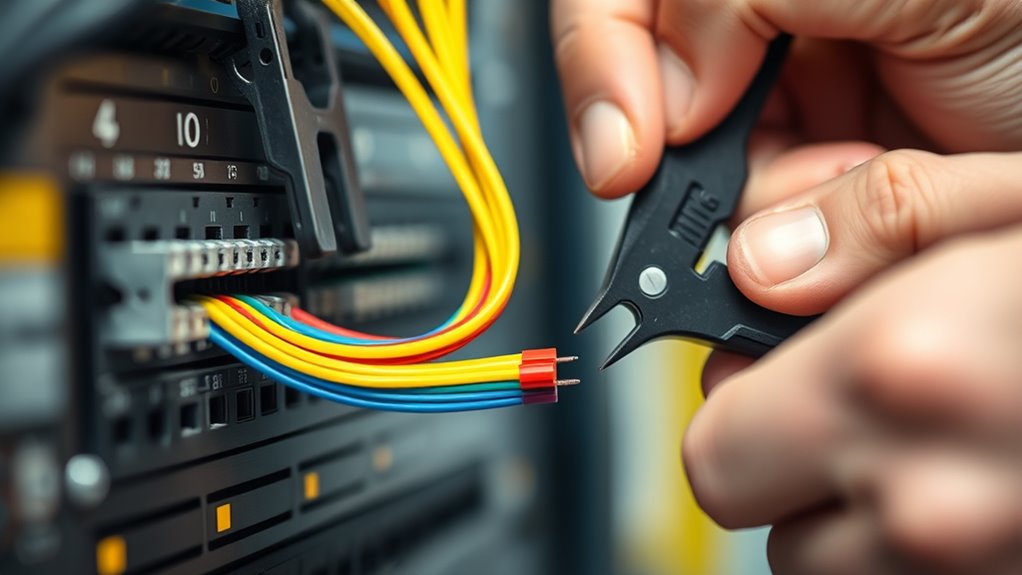

- Punch-down requires specialized tools like punch-down tools; crimping uses crimping pliers or crimpers for secure terminations.

- Punch-down connections are stable and long-lasting, while crimped connections are more resistant to environmental stresses.

- Choice depends on environment, application speed, cable type, and desired neatness or durability of the connection.

Klein Tools VDV427-300 Impact Punchdown Tool with 66/110 Blade, Reliable CAT Cable Connections, Adjustable Force, Includes Pick and Spudger

EFFICIENT TERMINATION: Punchdown tool terminates and cuts wires in CAT3, CAT5e, and CAT6/6A cable in a single step,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Overview of Termination Methods

Have you ever wondered how organizations end employment relationships effectively? While that’s about HR, in cable management, termination methods also matter. Different techniques, like punch-down and crimping, serve specific purposes. When choosing a method, consider cable flexibility—some techniques preserve more flexibility for future adjustments, making maintenance easier. Aesthetic considerations also influence your choice; neat, tidy terminations look better and improve overall cable organization. Punch-down methods often provide a clean, low-profile finish, ideal for structured wiring. Crimping, on the other hand, offers a robust connection suitable for applications where strength is key. Understanding these options helps you select the best termination technique for your needs, balancing flexibility and appearance to ensure reliable, professional results. Additionally, selecting the appropriate materials and tools can significantly impact the quality and durability of your cable connections. Proper training and experience can also improve the precision and effectiveness of your termination techniques.

Solsop Pass Through RJ45 Crimp Tool Kit Ethernet Crimper CAT5 Cat5e Cat6 Crimping Tool Kit

Fast, reliable RJ45 Crimp Tool for voice and data applications with Pass Through 50PCS RJ45 connector plug, 50PCS…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Tools and Materials Needed

To guarantee a proper termination, you’ll need specific tools designed for this task, such as wire strippers, crimpers, and screwdrivers. Alongside these, selecting the right materials like connectors, terminals, and insulation is essential for a secure connection. Knowing what tools and materials to gather sets the foundation for a successful termination process. Additionally, understanding the safety precautions associated with handling electrical components can help prevent accidents during the termination process. Proper wire management techniques can further ensure a reliable and organized connection, reducing the risk of faults or failures. Incorporating appropriate cable types ensures compatibility and optimal performance of the connections.

Tools Required for Termination

Proper termination requires specific tools and materials to guarantee a secure and reliable connection. To confirm connector compatibility and meet insulation requirements, you’ll need a punch-down tool or crimping tool suited for your connector type. A wire stripper is essential for removing insulation cleanly without damaging the conductor. A pair of precision cutters helps trim excess wire after termination. You should also have a cable tester to verify connections and a compatible storage container for organization. For crimping, select a crimping tool designed for the specific connector, ensuring proper fit and insulation handling. Always check the connector’s compatibility with your cable type and insulation specifications to avoid issues later. Using the right tools streamlines the process and ensures a professional, durable termination. Maintaining proper mental clarity during the process can help prevent mistakes and improve overall results. Additionally, understanding the different termination techniques, such as punch-down versus crimping, can aid in choosing the most suitable method for your project. Considering noise levels of tools can also improve comfort and efficiency during installation. Being aware of the tool maintenance needs is crucial to keep your equipment in optimal condition and prevent failures during critical moments.

Materials Needed for Connectors

What materials do you need to guarantee a secure and effective connector installation? First, identify the appropriate connector types for your project, such as RJ45, Keystone, or coaxial connectors. Next, verify your cables meet the required specifications, including wire gauge and insulation type, to match the connectors. You’ll need the correct tools, like crimpers, punch-down tools, or wire strippers, depending on the connector type. Additionally, use quality connectors that fit your cable specifications to ensure reliable connections. Keep spare connectors handy for testing and troubleshooting. Proper materials and compatible cable specifications are essential for a secure setup, preventing signal loss or disconnections. Always verify your materials match your project requirements for optimal performance. Ensuring compatibility with connector standards can help avoid issues during installation.

RJ45 Crimp Tool Kit Pass Thru Ethernet Crimper for Cat5e Cat6 Cat6a 8P8C Modular Connectors, All-in-One Cat6 Crimping Tool and Tester(9V Battery Not Included)

Professional RJ45 Crimper: Ethernet crimping tool kit includes RJ45 Crimper Pass Through,20PCS CAT6 Pass-Thru Connectors, 20PCS Connector Covers,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Application Scenarios for Punch-Down

Punch-down techniques are essential in various networking and telecommunications setups, especially when connecting individual wires to terminal blocks or patch panels. They’re commonly used in structured cabling systems for voice, data, and video connections. These techniques excel in environments where fiber optics and traditional copper cables coexist, providing reliable, secure connections. Punch-down methods are ideal for patch panels that serve as central points for managing multiple lines, making maintenance straightforward. While fiber optics often require splicing, punch-downs simplify connections in hybrid systems. They’re also useful in wireless connections infrastructure, such as access points and antenna distributions, where organized cabling is critical. Overall, punch-downs are a versatile choice for scenarios demanding durable, neat, and efficient wiring. structured cabling systems are designed to support a wide range of communication needs, making punch-down techniques a key component in maintaining organized and scalable networks. Additionally, the use of compatible tools ensures proper termination and reduces the risk of connection failures, further enhancing network reliability. Proper training and technique mastery are crucial to ensure secure and consistent connections in punch-down applications.

iMBAPrice – RJ45 Network Cable Tester for Lan Phone RJ45/RJ11/RJ12/CAT5/CAT6/CAT7 UTP Wire Test Tool

Automatically runs all tests and checks for continuity, open, shorted and crossed wire pairs. Visible LED status display.

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Application Scenarios for Crimping

Crimping is widely used in electrical and network installations to create secure, reliable connections quickly. For fiber optic applications, crimping connects connectors to cables efficiently, ensuring minimal signal loss and consistent performance. It’s also essential in wireless connectivity setups, where quick, durable terminations are necessary for antennas, adapters, and other components. Crimping offers a sturdy, vibration-resistant connection that withstands environmental stresses, making it ideal for outdoor or industrial environments. When speed and reliability matter, crimping allows you to complete installations without specialized tools or extensive training. Additionally, connection integrity is maintained through proper crimping techniques, which is crucial for long-term performance. Proper training and technique further enhance the effectiveness of crimping, reducing errors and improving overall reliability. Whether you’re working on fiber optic backbone networks or setting up wireless access points, crimping provides a practical solution for secure, long-lasting connections. Its versatility makes it a go-to technique in diverse scenarios requiring quick, dependable terminations, and understanding crimping tools is essential for achieving optimal results.

Installation Speed and Efficiency

Installation speed and efficiency are essential factors that can considerably impact your project timelines. Punch-down methods often require less cable manipulation, which can save time, especially with flexible cables that are easy to position. Ease of use can also influence how quickly technicians adapt to either technique, affecting overall speed. Crimping, on the other hand, may take more time initially due to the need for precise tool use and cable trimming, but it can streamline large-volume installations once mastered. Your technician training plays a significant role here; skilled technicians can work faster and more accurately with either technique. If your team is well-trained in punch-down methods, the installation process becomes quicker, thanks to straightforward procedures. Conversely, crimping benefits from familiarity with tools and techniques, leading to fewer errors and faster completion. Additionally, understanding installation speed factors can help optimize your workflow and reduce overall setup time. Moreover, technician skill level directly influences the speed and accuracy of either method, emphasizing the importance of proper training. For example, familiarity with the sound science behind tools and techniques can further improve efficiency. Overall, choosing the right method can boost your installation efficiency and meet project deadlines more effectively.

Connection Reliability and Durability

Choosing the right termination method directly influences how well your connections hold up over time. Crimping often provides a secure, consistent connection that resists loosening, making it ideal for long-term use. Punch-down connections, when done correctly, create solid contact points that withstand regular stress. If you’re considering wireless alternatives, these wired methods still provide a dependable backbone, especially where stability matters. Additionally, aesthetic considerations can impact your choice; crimped connectors often look cleaner and more professional, while punch-down terminations are more discreet in structured wiring panels. Proper termination techniques are especially important given the importance of connection reliability and durability**, which can be affected by factors like Pimple Patch technology in skincare. Using specialized hardware** ensures that your connections remain stable and reduce the need for frequent repairs or adjustments.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential to keep your network connections running smoothly. If you notice wireless connectivity issues, inspect your terminations for loose or damaged connections, as poor terminations can cause signal loss. Use a cable tester to identify faults quickly. Environmental impact also plays a role; extreme temperatures, humidity, or dust can degrade connections over time. Keep your work area clean and protected from environmental stressors to prevent deterioration. When troubleshooting, verify that termination techniques—whether punch-down or crimping—are correctly executed, as improper techniques can lead to intermittent problems. Periodic checks help you catch issues early, reducing downtime and maintaining excellent performance. Consistent maintenance ensures your network stays reliable, efficient, and less susceptible to environmental factors that could impair wireless connectivity.

Factors to Consider When Choosing a Technique

When selecting a termination technique, you need to take into account the reliability and strength of your connections to ensure long-term performance. Installation speed and ease can save you time and reduce errors, especially in tight schedules. Additionally, assess the equipment and tool requirements to determine if you have the necessary resources readily available.

Connection Reliability and Strength

The reliability and strength of a connection are essential factors to contemplate because they directly impact the durability and safety of the termination. A secure connection minimizes signal interference, ensuring consistent data transmission and reducing errors. Punch-down techniques typically provide stable, solid contacts, making them reliable for long-term use. Crimping, if done correctly, also offers strong, durable connections that resist loosening over time. Additionally, aesthetic considerations matter; neat, well-executed terminations reduce the risk of accidental disconnections or damage. A tidy setup with minimal exposed wiring not only enhances safety but also improves overall appearance. When choosing between punch-down and crimping, weigh the importance of connection stability against potential signal interference and how the finished look aligns with your project’s requirements.

Installation Speed and Ease

Choosing the right termination technique involves considering how quickly and easily you can complete the job. When working with fiber optics or in industrial settings, some methods streamline installation more than others. Punch-down techniques are often faster for bulk terminations and require minimal tools, making them ideal for quick setups. Crimping, on the other hand, can be more straightforward for repetitive tasks, especially with standardized connectors. If you’re installing in tight spaces or large networks, ease of use becomes essential. Consider the complexity of the cable type and the environment to choose the best method. Your goal is to reduce time without sacrificing quality, especially when handling fiber optics in demanding industrial settings. Efficient techniques save time and reduce errors during installation.

Equipment and Tool Requirements

Are your tools up to the task? Choosing the right termination technique depends on your equipment and tools. For fiber optic cables, you’ll need specialized connectors and a fiber cleaver, guaranteeing precise cuts. Crimping requires a good crimping tool compatible with your connector types, whether for Ethernet or coaxial cables. Punch-down tools are essential for structured wiring, especially for telecommunications. If you’re working on wireless connections, consider tools that facilitate quick, reliable terminations to minimize signal loss.

| Equipment/Tools | Key Features |

|---|---|

| Fiber Optic Crimpers | Precise, clean cuts; compatible with fiber optic connectors |

| Crimping Pliers | Securely attach connectors to Ethernet or coaxial cables |

| Punch-down Tool | Efficient for structured wiring, especially for telephone and data lines |

| Fiber Optic Cleaver | Ensures smooth, accurate fiber cuts for maximum signal transmission |

| Cable Strippers | Prepares cables for termination, reducing damage and guaranteeing quality |

Frequently Asked Questions

Which Termination Method Is More Environmentally Friendly?

You’ll find that punch-down termination tends to be more eco-friendly than crimping because it generates less waste and uses fewer materials. When comparing sustainability, punch-down methods often rely on eco-friendly materials and produce minimal scrap, making them a more sustainable choice. Plus, since they’re designed for durability and easy reuse, they help reduce environmental impact over time. So, if you’re aiming for a greener option, punch-down techniques are usually the better choice.

Can Punch-Down and Crimping Be Combined in One Installation?

Yes, you can combine punch-down and crimping in one installation, but you need to take into account compatibility issues. Some components may not work well together, which can affect installation flexibility and performance. It’s vital to plan carefully, ensuring connectors and cables are compatible with both techniques. This approach can be efficient, but double-checking compatibility prevents problems and ensures a smooth, effective setup.

Are There Specific Safety Precautions for Each Technique?

Oh, sure, because safety precautions are just optional, right? Actually, you should always follow safety protocols for each technique. When punch‑downing, handle the punch-down tool carefully to avoid injuries, and guarantee your workspace is clear. For crimping, use proper equipment handling to prevent slips or accidents. Always wear safety glasses and gloves if necessary. Ignoring these precautions can lead to injuries, so take safety seriously—your fingers will thank you.

How Do Costs Compare Over the Equipment’s Lifespan?

Over the long term, punch-down tools tend to be more cost-effective due to their durability and lower maintenance needs, which extend equipment longevity. Crimping tools may have higher initial costs and might require replacements sooner, increasing overall expenses. By choosing punch-down techniques, you reduce long-term costs and guarantee reliable performance, making it a smarter investment for sustained use.

What Training Is Recommended for Technicians Learning These Techniques?

You should pursue thorough training standards and certification programs to master these termination techniques. These programs teach you essential skills, best practices, and safety protocols, ensuring you’re proficient in punch-down and crimping methods. By completing accredited certifications, you demonstrate your expertise, which can boost your confidence and credibility. Continuous learning helps you stay updated on industry standards, ultimately improving your performance and reducing costly mistakes over the equipment’s lifespan.

Conclusion

Choosing between punch-down and crimping depends on your specific needs, like speed, reliability, and ease. Think of each method as a different brushstroke on your networking canvas—each creates a picture, but the style influences the final masterpiece. By understanding their strengths and limitations, you can craft a connection that’s both strong and lasting. Ultimately, the right technique helps you build a network that’s as resilient as a well-rooted tree.