Choosing the right cable stripping and cutting tools is vital for safe and precise electrical work. You should select from manual, automatic, rotary, or hydraulic options based on your project size and cable type. Prioritize ergonomic design, safety features, and blade quality to guarantee clean cuts and insulation removal. Proper use and maintenance help prevent accidents and prolong tool life. Continuing with this guide will give you essential tips to optimize your cable handling skills.

Key Takeaways

- Different types of cable stripping and cutting tools, such as manual, automatic, hydraulic, and rotary, suit various project needs.

- Proper tool selection enhances safety, efficiency, and quality of insulation removal and cutting accuracy.

- Safety precautions include wearing protective gear and inspecting tools before use to prevent accidents.

- Regular maintenance and correct storage of tools extend their lifespan and ensure optimal performance.

- Common mistakes include using dull blades, applying excessive force, and rushing, which can damage cables and compromise safety.

Types of Cable Stripping Tools

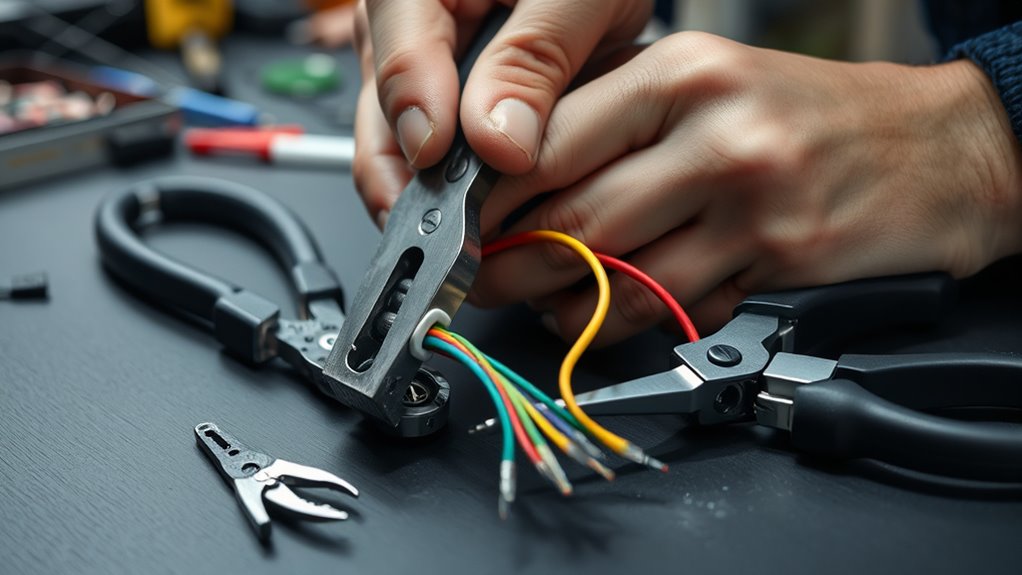

There are several types of cable stripping tools designed to make the job easier and more efficient. These tools are essential for insulation removal, especially when dealing with different cable diameters. A common option is the manual wire stripper, which allows you to adjust the stripping depth based on cable size, ensuring you don’t damage the conductor or remove too much insulation. Another popular choice is the automatic or self-adjusting stripper, which quickly adapts to various cable diameters with minimal effort. For larger or more specialized cables, rotary or oscillating tools provide precise insulation removal. Selecting the right cable stripping tool depends on your project’s needs and cable sizes, helping you work faster while maintaining clean, safe connections. Additionally, using hydrocolloid technology can help prevent damage to the appliance’s internal components and ensure safety during installation or repair. Proper selection of cable insulation removal tools can also reduce the risk of electrical faults caused by improper stripping techniques.

Types of Cable Cutting Tools

When choosing cable cutting tools, you’ll encounter handheld cable cutters, hydraulic cable shears, and rotary cable strippers. Each tool offers different advantages depending on the cable size and application. Understanding their features helps you select the right tool for your project. For specialized tasks, Mazda Tuning techniques can be applied to optimize performance and durability of related equipment. Additionally, selecting tools with advanced safety features can help prevent accidents during operation. Being aware of regional legal resources and regulations can also influence the selection of tools, especially in professional settings that require compliance with safety standards.

Handheld Cable Cutters

Handheld cable cutters are essential tools for efficiently cutting various types of cables in electrical and telecommunications work. Their ergonomic design ensures comfortable handling during extended use, reducing fatigue and increasing precision. You’ll find these cutters are built with high material durability, allowing them to withstand tough conditions and frequent use without losing sharpness or strength. The sharp blades enable clean, accurate cuts, minimizing cable damage and making installation or maintenance smoother. Whether you’re working with copper, aluminum, or fiber optic cables, handheld cutters provide portability and ease of use, making them ideal for on-the-go tasks or tight spaces. Investing in a well-designed, durable pair of handheld cable cutters helps you work faster, safer, and more efficiently. Additionally, choosing tools with proper cable compatibility ensures optimal performance and longevity.

Hydraulic Cable Shears

Hydraulic cable shears are powerful cutting tools that use hydraulic pressure to effortlessly cut through thick and heavy-duty cables. They offer high cutting efficiency, especially for larger cables that manual tools struggle with. When considering hydraulic shears, keep these key points in mind:

- Hydraulic pressure provides the force needed for clean, precise cuts.

- They are ideal for cutting multiple cables quickly without fatigue.

- The cutting efficiency reduces time and effort on demanding jobs.

- Their durable construction ensures longevity and reliable performance under tough conditions.

- Understanding cable material properties can help select the most suitable hydraulic shears for different applications.

- Proper maintenance of hydraulic systems ensures consistent performance and extends the lifespan of the shears.

- Familiarity with divorce process requirements can aid technicians in planning and executing safe and efficient cable removals in complex environments.

- Additionally, being aware of safety protocols when operating hydraulic shears is crucial to prevent injuries and ensure safe handling.

Rotary Cable Strippers

Rotary cable strippers are versatile tools designed to efficiently remove insulation from various cable types. They work well across different wire gauge compatibilities, making them suitable for a range of projects. These tools are especially effective on insulation types like rubber, PVC, and foam, providing clean cuts without damaging the conductor. The rotary mechanism allows you to rotate the tool around the cable, ensuring even stripping with minimal effort. You can easily adjust the blade depth to match the cable’s insulation thickness, preventing cuts into the wire itself. Because they are adaptable to different cable insulation types and wire gauges, rotary cable strippers are a reliable choice for electricians and DIY enthusiasts alike. They speed up the process while maintaining precision and safety. Proper use of cable stripping tools can help prevent damage to conductors and ensure safety during electrical work. Additionally, selecting the right cable stripping tool for your specific needs can significantly improve efficiency and safety on any project. Being familiar with cable insulation materials can further enhance your ability to choose the most suitable stripper for each task. Moreover, understanding safe handling techniques is essential to avoid accidents and ensure clean, effective cuts.

Features to Consider When Choosing Tools

When selecting cable stripping and cutting tools, it’s essential to focus on features that guarantee safety, efficiency, and durability. First, prioritize an ergonomic design to reduce hand fatigue during prolonged use. Second, choose tools made from high material durability to withstand frequent use without breaking down. Third, consider the precision of the blades to ensure clean cuts and strips every time. Fourth, verify the safety features, like lock mechanisms or blade guards, that protect you during operation. Additionally, look for comfortable grips that improve control and reduce slipping. These features not only enhance your safety but also boost productivity. By paying attention to ergonomic design and material durability, you guarantee your tools are reliable and effective for everyday tasks. Moreover, incorporating headphone compatibility considerations can ensure your tools are versatile for various electronic projects. Furthermore, understanding AI-driven features in modern tools can optimize your workflow and improve overall efficiency. Also, selecting tools with corrosion resistance can extend their lifespan even in challenging environments.

Manual vs. Electric Cable Strippers and Cutters

Manual cable strippers and cutters offer you precise control and portability, making them ideal for small-scale or occasional tasks. They excel when you need to select the correct wire gauge and ensure insulation compatibility without relying on power sources. With manual tools, you can easily adjust settings to match specific wire sizes, reducing the risk of damaging the conductor or insulation. They’re lightweight, easy to carry, and don’t require electricity, making them perfect for on-the-spot jobs or tight spaces. However, they may take more time and effort for larger projects. On the other hand, electric cable strippers and cutters can handle high-volume work quickly, often with automatic wire gauge detection. Consider your project scope, frequency, and the need for precision when choosing between manual and electric tools. Additionally, understanding types of paint sprayers can help you better appreciate the importance of proper tool selection and maintenance for optimal results. For larger or repetitive tasks, electric tools can significantly reduce fatigue and increase efficiency, especially when paired with tuning techniques that optimize tool performance.

Safety Tips for Using Cable Tools

To guarantee your safety while using cable tools, it’s essential to follow proper procedures and wear appropriate personal protective equipment. Always start with a thorough tool safety checklist to minimize risks. Here are crucial safety tips:

- Wear gloves, safety glasses, and long sleeves to protect against sharp cable ends and debris.

- Inspect your tools before each use to ensure they are in good condition.

- Keep your workspace clean and well-lit to avoid accidents.

- Maintain a firm grip and proper stance to prevent slips and mishaps.

- Be aware of evolving AI cybersecurity threats that could compromise your safety or tools. Additionally, understanding sound vibrations and their effects can help you stay aware of potential hazards during operation.

- Regularly review your safety procedures to stay updated on best practices and reduce the risk of injury.

Following these safety tips helps prevent injuries and ensures a smooth operation. Remember, adhering to your personal protective equipment requirements and a consistent tool safety checklist is vital for safe cable tool usage.

How to Properly Use Cable Stripping and Cutting Tools

Using cable stripping and cutting tools correctly is essential for safe and efficient work. To start, always measure the cable accurately to determine the length of insulation removal needed. Use a tape measure or cable gauge to mark the spot. When stripping insulation, select the appropriate blade or notch on your tool to avoid damaging the conductor. Gently clamp the cable and rotate the tool around the insulation to remove it smoothly. For cutting, position the cable securely and apply steady pressure, ensuring a clean cut without crushing the wire. Proper technique minimizes errors, prevents accidents, and maintains tool longevity. Remember to keep your work area organized and inspect tools regularly for wear, ensuring precise cable measurement and insulation removal every time.

Maintenance and Storage of Cable Tools

To keep your cable tools in top shape, you need to clean them regularly using proper techniques to eliminate dirt and residue. Organized storage solutions help prevent damage and make your tools easy to find when you need them. Taking these steps ensures your tools stay sharp, safe, and ready for use whenever required.

Proper Cleaning Techniques

Proper cleaning is essential for maintaining the effectiveness and longevity of your cable stripping and cutting tools. To do this effectively, follow these steps:

- Use cleaning brushes specifically designed to remove debris from blades and joints.

- Select a suitable solvent based on the material—oil-based or water-based—that won’t damage your tools.

- Dip the brush in the solvent and scrub all moving parts and blades thoroughly.

- Wipe down the tools with a clean cloth to remove excess solvent and dirt.

Organized Storage Solutions

Are your cable tools organized in a way that keeps them readily accessible and protected? Using a dedicated wire organizer guarantees your tools stay tidy and easy to find. Invest in a sturdy tool rack to store cutters, strippers, and other essentials, preventing damage and misplacement. Keep frequently used tools within arm’s reach, and designate specific spots for each item to streamline your workflow. Regularly inspecting your storage setup helps maintain order and prolongs tool life. Label shelves and compartments for quick identification, reducing downtime during projects. Proper organization not only improves efficiency but also minimizes safety hazards. By maintaining a clean, well-structured storage system, you’ll ensure your cable tools remain in top condition and ready whenever you need them.

Common Mistakes to Avoid During Cable Preparation

One common mistake during cable preparation is applying too much force when stripping insulation, which can damage the conductors or create uneven edges. To avoid this, make sure you select the correct blade for your cable type, as incorrect blade selection can lead to incomplete or over-cutting. Rushing the process often results in mistakes like nicking wires or damaging insulation. Here are some additional pitfalls to watch out for:

- Using dull blades that require more pressure

- Skipping the measurement of cable length before cutting

- Not securing the cable properly during stripping or cutting

- Ignoring manufacturer guidelines for specific cables

Recommendations for Different Wiring Projects

Choosing the right tools and techniques for each wiring project can make a big difference in the quality and safety of your work. For wireless cable installations, focus on precision tools that handle delicate connections without damage. Use specialized stripping tools to avoid nicking the insulation, especially when working with thin or flexible cables. For fiber optic projects, precision is critical; employ fiber optic cutters and strippers designed to prevent fiber damage and ensure clean cuts. When working on commercial or home wiring involving traditional cables, select appropriate wire strippers and cutters suited to the gauge. Always verify compatibility with your cable type to avoid mistakes. Proper tools and techniques streamline installation, improve performance, and reduce hazards across all wiring projects.

Frequently Asked Questions

Can I Use the Same Tool for Different Cable Types?

You can often use the same tool for different cable types if it offers good tool compatibility and cable versatility. Many modern stripping and cutting tools are designed to handle various cable sizes and materials, making them versatile. However, always check the manufacturer’s guidelines to confirm the tool suits the specific cable type you’re working with. Using the right tool for each cable ensures clean cuts and prevents damage.

What Is the Typical Lifespan of Cable Stripping Blades?

Your cable stripping blades typically last between 1,000 to 5,000 cuts, depending on blade durability and usage. You should expect to replace them more frequently if you work with tougher cables or perform heavy-duty tasks. Regularly check for dullness or nicks, and replace blades as needed to guarantee clean cuts and safety. Proper maintenance and sharpening can extend their lifespan, reducing replacement frequency over time.

Are There Eco-Friendly Options for Cable Cutting Tools?

Think of eco-friendly cable cutting tools like a gust of fresh air—you’ll love how they help the planet. You can find options made from biodegradable materials or recycled steel, which reduce environmental impact. These tools are durable and effective, so you don’t have to compromise on performance. By choosing such environmentally conscious tools, you actively contribute to sustainability while getting the job done efficiently.

How Do I Troubleshoot Common Issues With Cable Tools?

To troubleshoot common issues with cable tools, start by checking if the tool is properly calibrated; improper calibration can cause uneven cuts or stripping. If you notice dull blades or difficulty cutting, replace the blades promptly to restore performance. Also, verify the tool’s moving parts are clean and well-lubricated. Regular maintenance, including calibration and blade replacement, helps prevent problems and keeps your cable tools functioning smoothly.

Can Portable Cable Tools Be Battery Operated?

Yes, portable cable tools can be battery operated. Many modern cordless cable cutters and other battery-powered tools let you work without needing an external power source, making your job more flexible and efficient. These cordless cable cutters are designed for easy handling, allowing you to quickly cut or strip cables on the go. Just make sure the batteries are fully charged for peak performance, and you’ll have reliable, portable power at your fingertips.

Conclusion

Armed with the right cable stripping and cutting tools, you can transform tangled chaos into neat, precise wiring. Picture yourself effortlessly gliding through cables like a craftsman, sparks of confidence illuminating your workspace. With proper technique, safety, and maintenance, you’ll build a foundation of skill that turns complex projects into satisfying achievements. So grab your tools, envision your perfect setup, and let your craftsmanship power every connection you make.