When selecting fiber optic cleavers and cutters, you need tools that deliver precision, durability, and ease of use. The right kit can make a significant difference in your installation quality and efficiency. With so many options available, it’s important to understand which features matter most for your projects. Keep going to discover the top five kits that balance performance and practicality for professional results.

Fiber Optic Termination Tool Kit (9-in-1 FTTH Kit)

The Fiber Optic Termination Tool Kit (9-in-1 FTTH Kit) is your all-in-one solution for professionals who need a reliable, comprehensive set for fiber optic installation and maintenance. It includes essential tools like an optical power meter compatible with multiple connectors, a 30 km visual fault locator, fiber cleaver, stripper, and splicing tools. Designed for quick, precise work, it supports fiber preparation, fault detection, and splicing. Its lightweight, portable design makes it easy to carry and operate on-site. Whether you’re connecting, testing, or repairing, this kit streamlines your workflow, ensuring accurate results and efficient fiber optic management.

Best For: professional fiber optic installers and maintenance technicians seeking a comprehensive, portable toolkit for precise installation, testing, and repair tasks.

Pros:

- Includes a versatile 9-in-1 set of essential fiber optic tools for various tasks.

- Compatible with multiple connector types and suitable for long-distance fault localization.

- Lightweight, compact design enhances portability and ease of use on-site.

Cons:

- May require some technical experience to operate all tools effectively.

- Limited to the specific tools included; additional specialized equipment might be necessary for complex tasks.

- The kit’s durability and long-term performance depend on proper handling and maintenance.

SWANSOFT Fiber Cleaver with 3-in-1 Function and Gauge Wire Stripper

If you’re looking for a versatile and precise tool for fiber optic work, the SWANSOFT Fiber Cleaver with 3-in-1 Function and Gauge Wire Stripper is an excellent choice. Its high-precision tungsten steel blade provides clean cuts with minimal fusion loss, supported by adjustable height settings. The dual fiber break prevention system ensures stability during cutting, even in cold conditions. Made of durable magnesium alloy, it’s lightweight and drop-resistant. The included wire stripper handles various fiber sizes, while the automatic waste collection keeps your workspace tidy. Overall, it offers reliable performance and ease of use for installation, maintenance, and DIY projects.

Best For: DIY enthusiasts, fiber optic technicians, and beginners seeking a reliable, precise, and portable fiber cleaving tool for installation and maintenance tasks.

Pros:

- High-precision tungsten steel blade ensures clean, accurate cuts with minimal fusion loss.

- Durable magnesium alloy body provides drop resistance and long-term durability.

- Supports various fiber types and includes a comprehensive toolkit with wire stripper and waste collection.

Cons:

- Manual operation with extra setup steps may be less efficient for high-volume tasks.

- Fixed fiber holder requires manual alignment, adding extra steps to workflow.

- Locking blade carriage needs resetting after each cut, which could be slightly inconvenient during repetitive work.

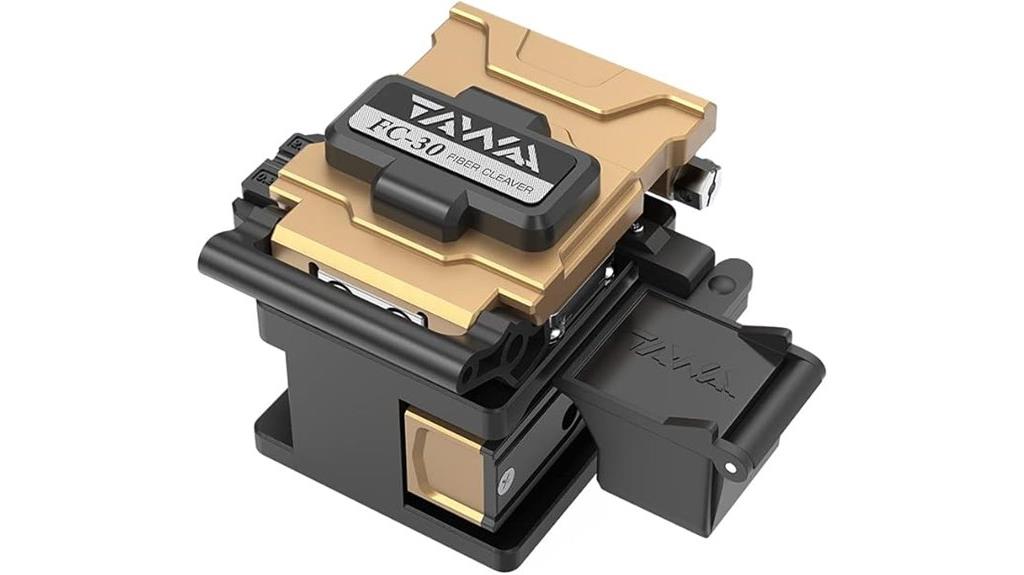

TAWAA FC-30 Fiber Optic Cleaver

Designed for professionals seeking precise, reliable fiber optic cuts, the TAWAA FC-30 Fiber Optic Cleaver offers high-precision performance with a typical angle of ≤0.5°. Its compact, bench-top design makes operation straightforward, featuring durable tungsten steel blades that resist wear and corrosion. With a blade life of up to 48,000 cuts, it handles fibers from 250μm to 3.0mm effortlessly. The ergonomic padded handle ensures comfort during extended use, while the built-in waste bin and silicone pressure pad improve efficiency and stability. Perfect for FTTH applications, this manual cleaver combines durability, accuracy, and ease of use in a lightweight, professional package.

Best For: professionals and technicians requiring precise, durable fiber optic cuts for FTTH installations and other field applications.

Pros:

- High-precision cutting angle ≤0.5° ensures accurate fiber cleaves.

- Durable tungsten steel blades with a blade life of up to 48,000 cuts for long-term use.

- Compact, lightweight design with ergonomic handle for comfortable extended operation.

Cons:

- Manual operation may require more effort compared to powered cleavers.

- Limited to fibers between 250μm and 3.0mm, not suitable for larger or non-standard fibers.

- No battery or electronic features, which might be a drawback for users seeking automated functionality.

High Precision Fiber Cleaver S-60C Optical Fiber Tool

For professionals seeking precise and reliable fiber preparation, the High Precision Fiber Cleaver S-60C stands out with its three-in-one fixture capable of handling fibers from 0.25mm to 3.0mm in diameter. It delivers a clean, smooth cut with an angle of about 0.8°, minimizing signal loss. The tungsten steel blade is sharp, wear-resistant, and capable of approximately 48,000 cuts. Its automatic knife return and anti-fiber breakage design ensure safety and efficiency. Plus, the detachable waste fiber collection box makes cleanup easy. Lightweight and compact, this tool is perfect for FTTH fiber optic applications, offering durability and precision in every cut.

Best For: professionals and technicians who require precise, durable, and efficient fiber preparation for FTTH and other optical fiber applications.

Pros:

- Provides highly accurate cutting angle of approximately 0.8°, ensuring minimal signal loss.

- Sharp, wear-resistant tungsten steel blade capable of around 48,000 cuts for long-lasting performance.

- Features a three-in-one fixture with sponge pressure blocks for stable, displacement-free fiber cutting.

Cons:

- Customer ratings are moderate at 3.5 out of 5 stars, indicating potential variability in user experience.

- Slightly higher weight (8.8 ounces) may affect portability for some users.

- Limited to fibers within 3.0mm diameter, which may not suit all fiber types or sizes.

Fiber Optic Termination Tool Kit (9-in-1 FTTH Kit)

The Fiber Optic Termination Tool Kit (9-in-1 FTTH Kit) stands out as an all-in-one solution for professionals who need reliable and versatile tools for fiber optic installation and maintenance. It includes essential components like an optical power meter compatible with multiple connectors, a 30km visual fault locator, FC-6S fiber cleaver, fiber optic stripper, and splicing tools. Its lightweight, compact design makes it easy to carry and operate, whether you’re stripping, cleaving, or testing fibers. Designed for comprehensive FTTH tasks, this kit simplifies fiber preparation, fault detection, and connections, ensuring precise and efficient work in indoor and outdoor environments.

Best For: Professional fiber optic installers and maintenance technicians seeking a comprehensive, portable toolkit for efficient indoor and outdoor fiber optic tasks.

Pros:

- All-in-one kit with essential tools including power meter, fault locator, cleaver, stripper, and splicing tools for streamlined workflow.

- Compact and lightweight design enhances portability and ease of use in various environments.

- Compatible with multiple fiber connector types (LC, FC, ST, SCAPC) for versatile testing and maintenance.

Cons:

- May require some user familiarity with fiber optic tools for optimal operation.

- Limited to the included components; additional specialized tools might be needed for complex projects.

- The kit’s compact size could be insufficient for large-scale or high-volume fiber optic deployment tasks.

Factors to Consider When Choosing a Fiber Optic Cleaver and Cutter Kit

When selecting a fiber optic cleaver and cutter kit, you need to consider compatibility with different fiber types to ensure optimal performance. Focus on cutting precision, angle, and tool durability to get clean, reliable results. Also, think about how easy the tools are to operate, their portability, and whether they fit your workspace needs.

Compatibility With Fiber Types

Choosing a fiber optic cleaver or cutter kit that matches your fiber types is essential for achieving precise and reliable cuts. Make sure the tool supports the fiber diameter you’re working with, such as 125μm for single-mode or multi-mode fibers. Check if it can handle various fiber types like ribbon fibers, loose buffer fibers, or armored cables, ensuring versatility for different projects. Verify that the fixture and blade design accommodate core sizes like 0.25mm, 0.9mm, or 3.0mm for accurate cuts across multiple fiber types. Also, confirm the tool’s compatibility with different coating and cladding materials to prevent damage and ensure clean cleaves. Proper compatibility minimizes the risk of damage and enhances the quality of your fiber termination process.

Cutting Precision and Angle

Achieving precise fiber cuts depends heavily on the cutting angle of your cleaver or cutter kit. A cutting angle less than 0.8° ensures minimal signal loss and high-quality splices. Precise angles, typically around 0.5° to 0.8°, produce smooth fiber ends that reduce insertion loss during splicing. Look for tungsten steel blades, which stay sharp and provide consistent, accurate cuts across multiple fibers. Adjustable blade height and stop blocks let you customize the angle for different fiber types, ensuring optimal results. The overall accuracy of your cleaver’s angle significantly impacts splice quality and connection reliability. Investing in a kit that offers precise angle control helps you achieve cleaner cuts, better performance, and more dependable fiber optic connections.

Tool Durability and Material

Opting for fiber optic cleavers and cutters made from durable materials ensures your tools last longer and perform reliably in demanding conditions. High-quality blades crafted from wear-resistant tungsten steel deliver precise cuts and withstand thousands of uses without dulling. The tool body, often made from magnesium alloy or reinforced plastics, resists impacts, drops, and harsh environments, keeping your equipment intact. Anti-slip silicone pads and resilient support components enhance stability, minimizing fiber breakage during cutting. Corrosion-resistant finishes and high-hardness parts further protect against rust and wear, extending the tool’s lifespan. Choosing well-constructed tools with sturdy materials not only boosts durability but also reduces the need for frequent replacements, offering consistent performance and better value over time.

Ease of Operation

When selecting a fiber optic cleaver and cutter kit, ease of operation plays a crucial role in ensuring efficient and accurate work. Look for tools with intuitive controls, minimal setup steps, and straightforward fiber positioning to reduce errors. Ergonomic handles and lightweight designs make extended use more comfortable, especially in the field. Clear markings, adjustable blade height, and simple locking mechanisms allow you to achieve precise cuts without extensive training. Automated or semi-automated features, like automatic blade return or waste collection, streamline the process and save time. Consistent, reliable performance with minimal adjustments helps you learn quickly and boost productivity. Prioritizing ease of use ensures smoother operation, fewer mistakes, and a more confident work experience.

Portability and Size

Considering portability and size is essential when choosing a fiber optic cleaver and cutter kit, especially if you frequently work in the field or tight spaces. A compact kit makes transport easier and fits into small storage areas, so you’re always ready to work. Lightweight tools, often under a pound, help reduce fatigue during long tasks or on-the-go repairs. Foldable or ergonomic designs improve ease of handling and storage, perfect for technicians moving between sites. Small-sized kits with built-in cases or pouches keep tools organized and accessible, saving you time. Portable fiber cleavers typically operate manually, without bulky power sources, allowing you to use them anywhere. Prioritizing size and portability ensures your tools are convenient, efficient, and ready whenever you need them.

Additional Features and Accessories

Choosing a fiber optic cleaver and cutter kit with additional features can significantly improve your workflow and results. Look for adjustable blade height and stop blocks to customize cuts for different fiber types, ensuring precision. Integrated waste collection boxes keep your workspace clean and simplify debris removal. Compatibility with various fiber sizes and types offers versatility for multiple projects. Multi-function accessories like gauge wire strippers and fiber recovery boxes expand your toolkit’s capabilities, saving you time and effort. Safety features such as locking blade carriages and anti-slip pads enhance user safety and stability during operation. These extras make your cutting process more efficient, precise, and safe, helping you achieve professional results with less hassle. Prioritize kits with these features to optimize your fiber optic installation tasks.

Conclusion

Choosing the right fiber optic cleaver and cutter kit ensures clean cuts, reliable splices, and efficient installations. Consider your project needs, fiber types, and ease of use when selecting a kit. With options like the FTTH 9-in-1, SWANSOFT, TAWAA, and high-precision models, you’ll find tools that deliver durability and precision. Invest in quality tools to improve your workflow and achieve professional results every time.