If you’re looking for the best fiber optic cleavers of 2025, I’ve got you covered. I’ve reviewed top models that offer high precision, durability, and ease of use, from automatic and adjustable tools to compact, field-friendly designs. These cleavers support various fiber types and boost splicing quality. Keep going, and I’ll share detailed insights and recommendations that help you choose the perfect tool for your needs.

Key Takeaways

- The list highlights top-rated fiber optic cleavers of 2025, emphasizing precision, durability, and ease of use.

- Reviews compare features such as blade quality, automatic functions, and compatibility with various fiber types.

- The top picks cater to professional, field, and research applications with portable, lightweight designs.

- Pros and cons are analyzed to help users select the most reliable, cost-effective fiber cleaver.

- Additional insights include maintenance tips, user support, and the latest innovations in fiber cleaving technology.

Sumitomo Latest Model Type-82C+ Fusion Splicer Welding Splicer Type-82C+ with FC-6S Fiber Cleaver in Stock

Package including: Fusion Splicer T-82C+ AC adapter ADC-1430 Cooling tray Carrying Case Charging cord Spare Electrodes Electrode(spare) ER-10...

As an affiliate, we earn on qualifying purchases.

Sumitomo Type-82C+ Fusion Splicer with FC-6S Fiber Cleaver

If you’re looking for a reliable fusion splicer that offers precise fiber cleaving, the Sumitomo Type-82C+ with FC-6S Fiber Cleaver is an excellent choice. Made in Japan, it matches Fujikura’s quality and features a user-friendly touch screen. Its dual heat oven allows for efficient splicing, supporting all METRO, LAN, FTTx, and ultra bend-insensitive fibers like EZ-Bend. The complete package includes everything you need—splicer, cleaver, power supply, and accessories. Customers praise its stability, ease of use, and low loss performance straight out of the box. It’s a solid investment for professional fiber splicing with reliable, precise results.

Best For: professional fiber optic technicians and installers seeking a reliable, precise fusion splicer with user-friendly features for all types of fiber applications.

Pros:

- Supports a wide range of fibers including ultra bend-insensitive types like EZ-Bend

- Features a touch screen and dual heat oven for efficient splicing and fiber handling

- Made in Japan, matching Fujikura’s renowned quality and durability

Cons:

- Powered by lithium polymer AAAA batteries which are not included, requiring additional purchase

- Relatively heavy at 30 pounds, may be less portable for field work

- First available in late September 2024, limiting immediate availability in some regions

SWANSOFT Fiber Cleaver, Fiber Cleaver Tool 16 Cutting Points & 36000 Cutting Times Optic Cutter Cleaver Fiber 3 in 1 Fiber Holder with 3 Gauge Wire Stripper for 0.25mm 0.9mm 3.0mm Fiber Optic Cleaver

【HIGH-PRECISION 16-FACE BLADE】-The SWANSOFT fiber cleavers is equipped with high-hardness tungsten steel blades. It has 3 adjustable height...

As an affiliate, we earn on qualifying purchases.

SWANSOFT Fiber Cleaver with 16 Cutting Points and 3-in-1 Fiber Holder

The SWANSOFT Fiber Cleaver stands out for its high-precision cutting capabilities, making it an ideal choice for professionals who demand exact fiber termination. Its tungsten steel blade features 16 cutting surfaces and 36,000 cutting points, ensuring precise cuts with an angle under 0.8° and fusion loss below 0.1 dB. The adjustable height modes allow for customized fiber positioning, optimizing cut quality. Built from durable magnesium alloy, it’s drop-resistant and long-lasting, with anti-slip silicone pads and magnetic supports for stability. Plus, the integrated waste box simplifies cleanup, and the included wire stripper adds versatility, making it suitable for various fiber types and professional applications.

Best For: professionals and technicians needing precise, durable, and versatile fiber optic cutting and stripping tools for installation, maintenance, and research.

Pros:

- Extremely precise cuts with less than 0.8° angle and under 0.1 dB fusion loss

- Durable magnesium alloy construction with drop resistance and stable support features

- Multi-functional with adjustable height modes, waste collection box, and included wire stripper

Cons:

- May be more expensive compared to basic fiber cleavers and strippers

- Slightly heavier than simpler, non-metallic models, affecting portability for some users

- Requires proper handling to maximize precision and maintain blade sharpness

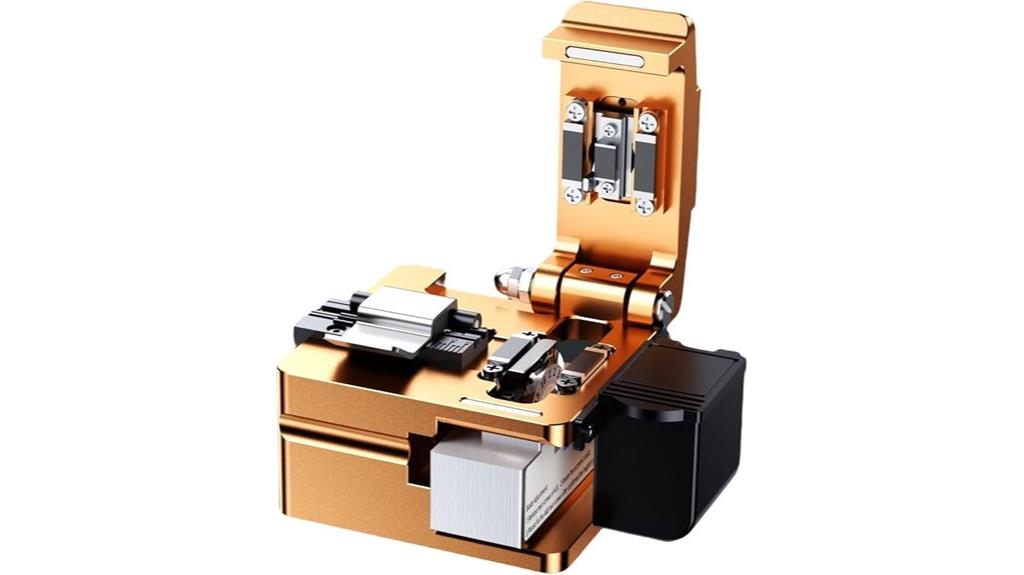

High precision Fiber Cleaver S-60C Optical Fiber Cleaver with 16 point cutting end face capable of cutting approximately 48000 times FTTH fiber tool with 1 spare blade and 2-in-1 stabilizer

【 Features 】 Three in one fixture, smooth cutting, tungsten steel blade, automatic knife return, hot melt cold...

As an affiliate, we earn on qualifying purchases.

High Precision Fiber Cleaver S-60C with 16-Point Cutting End Face

The High Precision Fiber Cleaver S-60C stands out for its 16-point cutting end face, making it an ideal choice for professionals demanding consistent, high-quality fiber cuts. It can perform approximately 48,000 cuts, thanks to its sharp, wear-resistant tungsten steel blade. Its three-in-one fixture accommodates various fiber types, including bare fibers, tail fibers, and patch cords. Features like sponge pressure blocks ensure stable, precise cuts while preventing displacement. The device also offers automatic knife return, hot melt cold welding, and a detachable waste collection box for easy cleaning. Overall, the S-60C combines durability, accuracy, and user-friendly design for reliable fiber termination.

Best For: Professionals and technicians requiring precise, high-volume fiber optic termination with consistent, high-quality cuts.

Pros:

- High cutting capacity with approximately 48,000 cuts and 16-point cutting end face for durability and reliability.

- Versatile fixture supports various fiber types including bare fibers, tail fibers, and patch cords.

- Features like automatic knife return, sponge pressure blocks, and detachable waste box enhance ease of use and safety.

Cons:

- May be more expensive compared to basic fiber cleavers, impacting budget-conscious users.

- Requires some training to maximize its advanced features and achieve optimal results.

- Bulkier design might be less suitable for very tight or confined workspace environments.

High precision Fiber Optic Cleaver A-S2 automatic rebound suitable for 0.25 0.9 3.0mm fiber, Cleaver Angle<0.6 ° Can be cut approximately 50000 times, with 1 spare blade

【 Features 】 Strong rust prevention, three in one fixture, smooth cutting, tungsten steel blade, automatic knife return,...

As an affiliate, we earn on qualifying purchases.

High Precision Fiber Optic Cleaver A-S2

For professionals seeking pinpoint accuracy in fiber optic preparation, the High Precision Fiber Optic Cleaver A-S2 stands out with its automatic rebound feature and precise 0.6° cutting angle. It handles fibers from 0.25mm to 3.0mm, offering about 50,000 cuts with minimal wear thanks to its tungsten steel blade. The device features rust prevention, a three-in-one fixture, and a built-in waste fiber box for convenience. Its automatic knife return guarantees smooth operation, while sponge pressure blocks stabilize fibers during cutting. Lightweight and durable, the A-S2 delivers consistent, high-quality cuts ideal for fiber splicing and welding, making it a reliable tool for demanding applications.

Best For: professionals and technicians requiring precise, high-volume fiber optic cutting for splicing, welding, and installation projects.

Pros:

- Offers approximately 50,000 clean, accurate cuts with minimal blade wear.

- Equipped with automatic rebound and knife return for efficient, smooth operation.

- Compatible with multiple fiber sizes (0.25mm, 0.9mm, 3.0mm) and includes a built-in waste fiber box for convenience.

Cons:

- Initial units may have functional issues, requiring replacements or adjustments.

- Relies on manual operation without batteries, which may limit automation.

- Customer reviews indicate a moderate satisfaction level (~3 stars), suggesting room for quality improvements.

Optical Fiber Cleaver with High Precision and Scrap Collector

Optical fiber cleavers with high precision and scrap collectors are essential tools for technicians who demand clean, accurate cuts and efficient waste management. I’ve found that these cleavers deliver superb performance, with less than a 0.5° cutting angle for ideal fiber ends, perfect for fusion splicing. The adjustable, compatible fiber holder supports 8–20mm cleave lengths, fitting both 250µm and 900µm fibers. Built to last from durable materials, they’re lightweight and easy to maintain. With up to 48,000 cuts across 16 cleave positions, these tools reduce downtime, ensure consistent quality, and make field and lab work more efficient.

Best For: fiber technicians and splicers requiring high-precision, durable cleavers with efficient scrap collection for field and lab applications.

Pros:

- Delivers clean, precise cleaves with less than 0.5° cutting angle for optimal fiber ends.

- Adjustable holder supports a wide range of cleave lengths and fiber types, enhancing versatility.

- High durability and long blade life up to 48,000 cuts reduce maintenance and downtime.

Cons:

- May be more expensive than basic cleavers due to advanced features and build quality.

- Requires proper handling and calibration to maintain cutting accuracy over time.

- The size and weight might be less suitable for very tight or constrained working environments.

SWANSOFT Fiber Cleaver, 3-in-1 Fiber Optic Cutter with Gauge Wire Stripper

If you’re seeking a versatile tool that combines precision cutting with added functions, the SWANSOFT Fiber Cleaver is an excellent choice. It features a tungsten steel blade with 16 cutting surfaces and 36,000 cutting points, ensuring accurate cuts with an angle under 0.8° and minimal fusion loss. Its adjustable height modes allow for tailored fiber positioning, enhancing cut quality. Made from durable magnesium alloy, it’s drop-resistant and stable, even in cold conditions. Plus, it supports multiple fiber types and includes an automatic waste collector, making cleanup quick. The integrated wire stripper adds further convenience, making this tool ideal for various fiber optic tasks.

Best For: professionals and technicians involved in fiber optic installation, maintenance, and research seeking a durable, precise, and versatile cutting and stripping tool.

Pros:

- High-precision tungsten steel blade with 16 cutting surfaces and 36,000 cutting points for accurate, low-loss cuts

- Durable magnesium alloy construction with anti-slip and drop-resistant features for long-term reliability

- Supports multiple fiber types and includes an automatic waste collection box for efficient workflow

Cons:

- Slightly heavier than basic cutters at 0.66 pounds, which may affect portability for some users

- May require some practice to fully utilize adjustable height modes for optimal cuts

- Limited to fiber optic and wire stripping applications, not suitable for other cable types

FC-71S Optical Fiber Cleaver, High Precision Fiber Cutter with Waste Fiber Box

The FC-71S Optical Fiber Cleaver stands out as an ideal choice for professionals who need precise, consistent cuts in fiber optic cables. Its high-precision design guarantees an angle of less than 0.8°, perfect for fusion splicing. With a built-in fiber holder, it handles 0.25mm, 0.9mm, and 3.0mm fibers, and features a readable scale for cleave lengths from 5 to 25mm. The tungsten steel blade offers up to 48,000 cuts, and the automatic knife return simplifies operation. Lightweight and durable, it’s suitable for field use, labs, and technicians seeking reliable, clean, precise fiber cuts every time.

Best For: professionals and technicians requiring precise, reliable fiber optic cable cleaving for splicing, laboratory work, and field installations.

Pros:

- High-precision cleaving with less than 0.8° angle for optimal fusion splicing.

- Durable tungsten steel blade with up to 48,000 cuts, reducing replacement frequency.

- Easy operation with automatic knife return and built-in fiber holder for various fiber sizes.

Cons:

- Manual crank operation may require more effort compared to powered cleavers.

- Slightly larger size may be less portable for very tight workspaces.

- Limited to fiber cleaving; not suitable for other types of cable cutting.

Pen Type Fiber Optic Cleaver and Marking Tool

A pen-type fiber optic cleaver and marking tool stands out for its portability and ease of use in field and laboratory settings. Made from tungsten carbide, it offers exceptional hardness, wear resistance, and thermal stability, ensuring durable performance. Its sharp blade cuts bare fibers cleanly and flat, producing burr-free ends that minimize signal loss. The compact pen design makes it easy to carry, clip into pockets, and handle comfortably during on-site repairs or lab work. Plus, the replaceable oblique blade lets you adapt to different cutting needs quickly, making this tool versatile and reliable for connector manufacturing, maintenance, and fiber preparation.

Best For: technicians, engineers, and laboratory personnel who need a portable, durable, and precise tool for fiber optic end face cutting and marking during installation, maintenance, or testing.

Pros:

- Made from tungsten carbide, ensuring exceptional hardness, wear resistance, and thermal stability.

- Sharp, flat blade produces burr-free, low-loss fiber end faces for optimal signal transmission.

- Compact pen-style design allows easy portability, pocket clipping, and comfortable handling in the field or lab.

Cons:

- Blade replacement requires some manual effort and care to ensure proper installation.

- Limited to end face cutting; not suitable for other fiber preparation tasks.

- May require additional tools for marking or detailed fiber handling in complex applications.

BAOSHLA Fiber Optic Termination Tool Kit (5-piece)

Designed for professionals demanding durability and precision, the BAOSHLA Fiber Optic Termination Tool Kit (5-piece) offers five essential tools optimized for field splicing and termination tasks. It includes an optical fiber cleaver with a tungsten steel blade rated for 48,000 cuts, ensuring clean, accurate cleaves every time. The kit also features three-port fiber strippers and a 3.0 mm x 2.0 mm stripper, making removal of coating layers straightforward without damaging the fiber core. Additionally, the cable scissors handle steel wires within cables for versatile use. These tools are reliable, easy to operate, and built for demanding environments, making this kit a practical choice for professional fiber optic work.

Best For: professional fiber optic technicians and installers seeking durable, precise tools for field splicing and termination tasks.

Pros:

- Durable tungsten steel blade with a long lifespan of 48,000 cuts for reliable use.

- Includes versatile tools such as three-port fiber strippers and cable scissors for various installation needs.

- Designed for ease of operation, making it suitable for demanding field environments.

Cons:

- May be heavier or bulkier compared to smaller, more portable kits.

- The set is limited to five tools, which might require additional equipment for specialized tasks.

- Not suitable for beginners due to the precision required for fiber optic work.

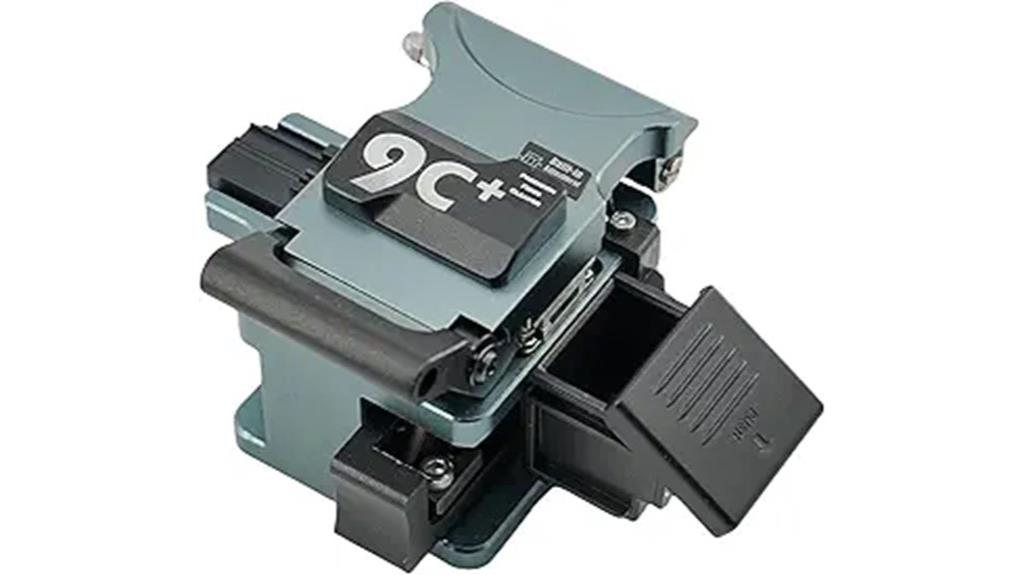

9C+ Optical Fiber Cleaver with Auto Rotate Blade, One-Hand Operation

If you need a reliable fiber cleaver that combines precision with ease of use, the C+ Optical Fiber Cleaver with Auto Rotate Blade is an excellent choice. It features a high-precision auto-rotate blade, enabling up to 48,000 clean, flat cuts with an angle ≤0.5°. Its one-handed operation, smooth slide rail, and automatic reset make it easy to handle, even in tight spaces. Built from superhard aluminum alloy and Tungsten Steel, it’s durable and maintains sharpness over extensive use. Compact and ergonomic, with rubber cushions and a fiber collector, this cleaver offers stability, efficiency, and portability, perfect for professional fiber optic work.

Best For: professionals and technicians seeking precise, efficient, and durable fiber cleaving tools for high-volume optical fiber preparation.

Pros:

- High-precision auto-rotate blade supports up to 48,000 clean cuts with a flat cleave angle ≤0.5°

- One-handed operation with smooth slide rail and automatic reset for convenience and ease of use

- Durable construction from superhard aluminum alloy and Tungsten Steel ensures long-lasting sharpness and stability

Cons:

- Slightly heavier compared to simpler manual cleavers, which may impact extended handheld use

- Limited to cutting fibers with bare diameter of 125μm and specific length range (7-16mm)

- No battery or power source required, which might limit automation options for some users

Factors to Consider When Choosing a Fiber Optic Cleaver Review

When choosing a fiber optic cleaver, I focus on cutting precision standards and compatibility with different fiber types to guarantee clean, reliable cuts. I also consider blade durability and ease of operation, since these impact long-term performance and user convenience. Finally, portability and size matter, especially if I need a tool that’s easy to carry and fits into tight spaces.

Cutting Precision Standards

Achieving high cutting precision in fiber optic cleavers is vital for guaranteeing minimal signal loss and ideal splicing. The key metric here is the cleave angle, with top-quality tools aiming for less than 0.8°, ideally around 0.6° to 0.8°, to produce smooth, flat fiber ends. Consistency is essential; a stable cleave angle reduces insertion loss and improves splice quality. The sharpness of blades and the number of cutting points, such as 16 or more than 36,000 cuts, help maintain precision over time. Low fusion loss, typically under 0.1 dB, indicates clean, defect-free fiber ends. Adjustable features, like variable cleave length and height modes, allow customization and guarantee the cleaver meets strict precision standards for different fiber types.

Compatibility With Fibers

Selecting a fiber optic cleaver that matches your specific cable types and sizes is vital for ensuring clean, reliable splices. I always check if the cleaver supports the fiber diameters I use, like 125μm or 250μm, to prevent any mishaps. Compatibility with both single-core and ribbon fibers is essential, especially if my projects involve diverse cable types. I also verify if the cleaver can handle different sizes, such as 0.25mm or 3.0mm fibers, so I don’t need multiple tools. Additionally, I consider whether the device can work with specialty fibers, like ultra bend-insensitive types. Adjustable fixtures and precise cutting features help me customize the cleaver to my specific fiber materials and configurations, ensuring peak performance.

Blade Durability and Life

The durability of a fiber optic cleaver’s blade is a key factor that can make or break your project’s success. High-quality blades typically last between 16,000 to 50,000 cuts, depending on the material and usage. Tungsten steel blades are especially valued for their hardness and wear resistance, allowing for longer service life and consistent performance. Regular blade replacement is essential to maintain precise, low-loss, burr-free cleaves, especially once the blade shows signs of dullness or reaches its maximum cut count. Investing in a cleaver with a durable blade and high cut capacity reduces downtime and ongoing maintenance costs. Ultimately, choosing a cleaver with robust blade endurance ensures you can rely on clean, precise cuts throughout your project without frequent replacements.

Ease of Operation

When choosing a fiber optic cleaver, ease of operation plays a significant role in ensuring smooth, efficient work, especially in demanding field or lab environments. A one-hand operation design allows me to quickly and confidently make cuts without hassle. Clear, adjustable fiber holding mechanisms and simple blade replacement processes make the tool user-friendly and reduce downtime. High-precision cleavers with automatic knife return and auto-rotate blades streamline the process, minimizing manual adjustments. An ergonomic handle and lightweight build improve maneuverability and help prevent fatigue during extended use. Visual indicators or scales for cleave length and angle enable me to achieve consistent, precise cuts with minimal training. Overall, these features combine to make fiber cleaving faster, easier, and more reliable.

Portability and Size

A compact and lightweight fiber optic cleaver makes all the difference when working in the field. A size of 2-4 inches ensures easy transport and quick handling, which is essential in tight or remote spaces. Weighing less than a pound, these models greatly reduce user fatigue during long sessions and enhance mobility. Foldable or ergonomic designs allow for one-handed operation and rapid deployment, saving time during critical tasks. Small-sized cleavers are especially useful for onsite splicing, maintenance, and training, where space is limited. Additionally, the right size can improve stability during cutting, leading to cleaner, more precise fiber ends. Overall, choosing a portable cleaver means better efficiency and comfort, making it a key factor in selecting the best tool for fieldwork.

Maintenance and Support

Choosing a fiber optic cleaver that’s easy to transport and handle is just the first step; maintaining it properly guarantees consistent, reliable performance over time. I look for brands that offer accessible customer support and readily available spare parts like blades and replacement components, ensuring I can keep my equipment in top shape. It’s crucial to verify if warranties or service plans cover repairs or replacements, especially for high-precision tools used in critical applications. I also value comprehensive user manuals and online resources that help troubleshoot and perform maintenance easily. Devices designed for straightforward blade replacement and cleaning tend to last longer and perform better. Finally, I prioritize vendors that provide technical assistance or repair services, giving me peace of mind during critical fiber optic tasks.

Frequently Asked Questions

What Maintenance Is Required for Fiber Optic Cleavers?

I make certain to regularly clean my fiber optic cleaver’s blade with a lint-free cloth and isopropyl alcohol to keep it free of dust and debris. I also check the blade for dullness and replace it if needed to guarantee clean cuts. Additionally, I keep the device stored in a dry, safe place and periodically inspect for any loose parts or damage to maintain peak performance.

How Do Environmental Conditions Affect Cleaver Performance?

Environmental conditions considerably impact cleaver performance. I notice that humidity causes corrosion on blades, reducing cutting precision. Extreme temperatures can make materials more brittle or soft, affecting clean cuts. Dust and dirt can clog mechanisms, leading to jams or inaccurate cleaves. To maintain ideal performance, I always store my cleaver in a dry, temperature-controlled environment and regularly clean and inspect it for any debris or corrosion.

Are There Specific Cleavers for Different Fiber Types?

Think of fiber types as different languages, each needing a translator. Yes, there are cleavers designed specifically for single-mode, multimode, or specialty fibers. These specialized tools guarantee precise cuts without damaging the delicate cores. Using the right cleaver is like choosing the right key for a lock—it’s crucial for peak performance and reliable connections. I always recommend matching your cleaver to your fiber type for the best results.

What Safety Precautions Should Be Taken When Using a Fiber Cleaver?

When using a fiber cleaver, I always wear safety glasses to protect my eyes from tiny glass shards. I make sure to handle the cleaver carefully, keeping my fingers clear of the blade. I also work in a clean, well-lit area to avoid accidents. After cutting, I dispose of any glass debris properly. Staying cautious helps me avoid injuries and guarantees precise, safe fiber splicing.

How Long Do Fiber Cleavers Typically Last With Proper Use?

With proper care, I’ve seen fiber cleavers last up to several years, sometimes even five or more. Imagine the precision blades slicing through fiber effortlessly, maintained with regular cleaning and careful handling. The key is avoiding rough use or dirt buildup. When I keep my cleaver sharp and store it properly, it continues to deliver clean, perfect cuts, making it a reliable tool that stands the test of time.

Conclusion

Choosing the right fiber optic cleaver can make all the difference in your project’s success. Did you know that a high-quality cleaver can improve splice accuracy by up to 30%? Investing in top-rated tools guarantees cleaner cuts, fewer rework, and better signal quality. I hope this list helps you find the perfect cleaver for your needs. Remember, the right tool isn’t just an expense—it’s an investment in your work’s precision and reliability.