Did you know that even a small 5% imbalance in DCRU can indicate a potential fault in your electrical system? Understanding how resistance differences between phases can signal issues is vital for maintaining system health. If you’re not monitoring these variations regularly, you might miss early warning signs of insulation failure or winding problems. Curious how DCRU testing can help prevent costly failures before they happen?

Key Takeaways

- DCRU measures resistance differences between phases or conductors, indicating system health when balanced.

- Imbalances often signal insulation deterioration, loose connections, or winding faults.

- Measurement involves applying small DC current and recording voltage drops with resistance meters.

- Regular DCRU testing during maintenance helps detect faults early, preventing failures.

- Deviations in resistance readings reflect potential issues like insulation degradation or short circuits.

Have you ever wondered what DCRU stands for and why it matters? DCRU, or Direct Current Resistance Unbalance, is a critical parameter in electrical systems, especially when it comes to guaranteeing safety and reliability. Understanding what DCRU represents helps you grasp how to detect issues early and prevent costly failures. At its core, DCRU measures the difference in resistance between phases or conductors in a system. When these resistances are balanced, it indicates that the system operates normally. But when there’s an imbalance, it can be a sign of underlying problems, such as insulation deterioration, loose connections, or winding faults. Recognizing these signs allows you to take proactive steps before a failure occurs.

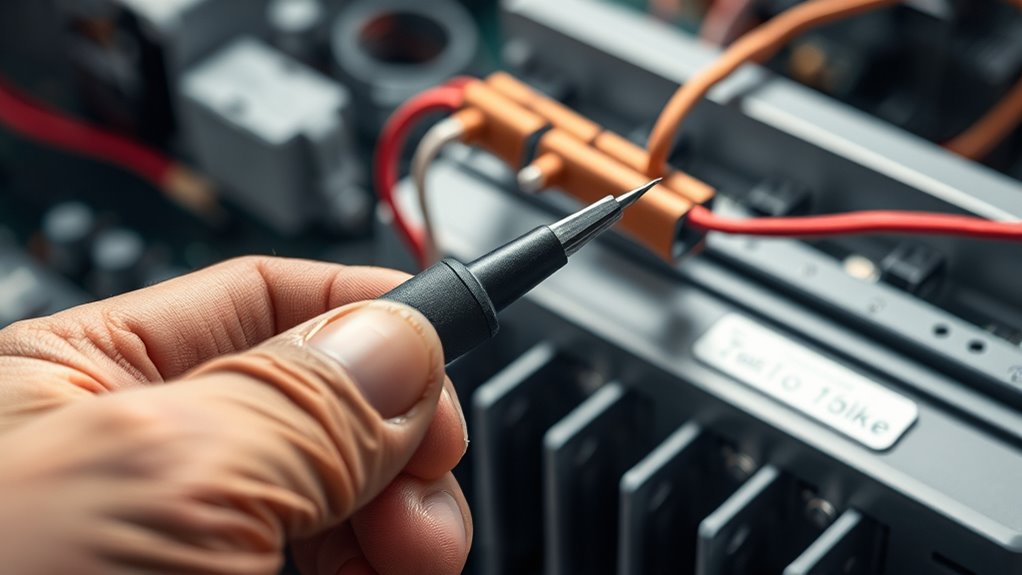

Measurement techniques are essential in accurately evaluating DCRU. Typically, technicians use specialized instruments like micro-ohmmeters or resistance meters to perform these tests. These devices send a small, controlled DC current through the conductor and measure the resulting voltage drop to determine resistance precisely. The key is to perform these measurements under consistent conditions, such as at the same temperature and with stable connections, to ensure reliable results. By systematically measuring resistance across different phases or conductors, you can detect even subtle unbalances that might not be apparent visually. This process becomes an integral part of routine maintenance, especially in critical systems like transformers, motors, or generator windings, where early fault detection can save significant money and downtime. Regular testing of resources and tools can help maintain system integrity and extend equipment lifespan.

Fault detection through DCRU evaluation is straightforward yet powerful. When the resistance readings show a deviation beyond acceptable limits, it signals a potential fault. For example, a higher resistance in one phase could indicate insulation degradation or a developing open circuit. Conversely, an unexpectedly low resistance might suggest a short circuit or bridging issue. By continuously monitoring DCRU, you can identify trends over time, which helps in planning maintenance before a fault causes a system failure. This proactive approach minimizes unexpected outages, improves system efficiency, and enhances safety for personnel working with electrical equipment.

Top picks for "resistance unbalance dcru"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Does DCRU Affect Overall Electrical System Efficiency?

DC Resistance Unbalance (DCRU) impacts your system efficiency by causing uneven current flow, which increases power loss. When resistance unbalances, certain parts of your system work harder, wasting energy and reducing overall efficiency. This inefficiency can lead to higher operational costs and potential damage over time. By monitoring and correcting DCRU, you help guarantee your electrical system runs smoothly and minimizes unnecessary power loss.

What Are Common Causes of DCRU in Power Cables?

Think of power cables as delicate threads prone to fraying. Common causes of DCRU include insulation degradation, which loosens the cable’s protective barrier over time, and manufacturing defects that create uneven resistance. Environmental factors like moisture or temperature changes accelerate insulation breakdown, while poor manufacturing can introduce inconsistencies from the start. Regular inspections and quality control help catch these issues early, ensuring your system runs smoothly.

Can DCRU Be Completely Eliminated in Existing Systems?

You can’t completely eliminate DCRU in existing systems, but you can reduce it substantially. Focus on proper material selection, choosing cables with consistent conductor properties, and follow best installation practices to minimize unbalance. Regular maintenance and testing help identify issues early. While perfect balance is challenging, these steps ensure your system operates efficiently, reducing the risk of equipment damage and improving overall reliability.

What Testing Methods Are Most Reliable for Detecting DCRU?

Detecting DCRU is like finding a needle in a haystack, but reliable methods include insulation resistance testing and contact resistance measurements. These tests identify issues caused by insulation degradation or increased contact resistance, which contribute to unbalance. You should perform these tests regularly with a micro-ohmmeter or clamp meter, ensuring accurate detection of DCRU. Consistent testing helps prevent failures and maintains system reliability.

How Often Should DCRU Measurements Be Performed?

You should perform DCRU measurements during your regular inspection frequency, typically every 6 to 12 months, depending on your equipment’s criticality and operating environment. Incorporate these tests into your maintenance schedule to catch issues early and prevent failures. Regular measurements help guarantee your system remains balanced, reducing risks and maintaining peak performance. Adjust your inspection and maintenance routines as needed based on past test results and manufacturer recommendations.

Conclusion

By keeping an eye on DCRU, you’re like a vigilant guardian watching over your electrical system’s heartbeat. When resistances stay balanced, everything hums smoothly like a well-tuned orchestra. But if unbalance creeps in, it’s a warning shot — a flicker of trouble ahead. Regular testing is your shield, catching issues early and preventing costly breakdowns. Stay proactive, and your system will thrive like a mighty oak standing tall against the storms.