When you consider the complexity of modern vehicles, cable harnesses play a critical role in ensuring all electronic systems work seamlessly together. They organize and protect the wiring that connects sensors, modules, and control units, all while withstanding challenging environments. But how these harnesses are designed and integrated can markedly impact vehicle safety and reliability — a topic that’s worth exploring as automotive technology evolves.

Key Takeaways

- Cable harnesses organize and protect multiple wires, ensuring efficient signal transmission within vehicle networks.

- They are designed with routing channels, clips, and conduits to secure wires and prevent damage from vibration and heat.

- Connectors integrated into harnesses facilitate modular assembly, quick maintenance, and reliable connections between components.

- Selection of harness materials and connector types depends on environmental durability, compatibility, and system requirements.

- Proper harness design reduces electrical noise, prevents shorts, and enhances overall network reliability and safety.

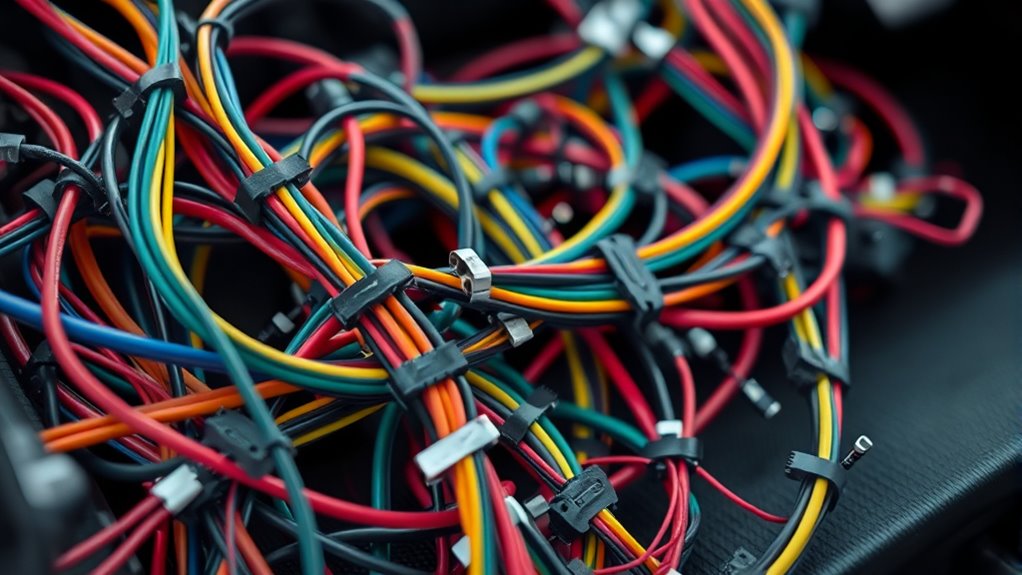

Have you ever wondered how modern cars seamlessly connect their electronic systems? It’s all thanks to a carefully designed network of cable harnesses that organize and protect countless wires running throughout your vehicle. One essential aspect of these harnesses is wire routing, which involves strategically planning the paths that wires take inside the car’s chassis. Proper wire routing ensures that signals flow efficiently without interference, reduces the risk of damage, and makes maintenance easier. When designing these routes, engineers consider factors like space constraints, vibration, heat sources, and accessibility. They often use specialized channels, clips, and clips to keep wires securely in place, preventing chafing or disconnection over the vehicle’s lifespan. Additionally, advancements in wire routing techniques have further improved system reliability and ease of assembly.

Equally significant are the connector types used within these harnesses. Connectors serve as the critical links that join different electronic modules, sensors, and control units. You’ll find a variety of connector types designed for specific functions, environments, and durability requirements. Some connectors are weather-resistant, ensuring reliable connections even in harsh conditions, while others are designed for quick disconnection for maintenance or repairs. When selecting connector types, engineers evaluate factors like pin configuration, locking mechanisms, and material composition to guarantee a secure fit and minimal signal loss. The right connector type can make a substantial difference in the reliability and longevity of your vehicle’s electrical system.

In practice, wire routing and connector types work hand-in-hand to create a robust and reliable network. As you look under the hood or inside the dashboard, you’ll notice how wires are neatly bundled and routed along designated paths, often with protective sleeves or conduits. The connectors at each end are carefully chosen to match the specifications of the modules they connect to, ensuring compatibility and preventing accidental disconnections. This meticulous attention to wire routing and connector selection minimizes electrical issues, such as shorts or noise, which could impair vehicle performance.

Frequently Asked Questions

How Do Cable Harnesses Impact Vehicle Safety Systems?

Cable harnesses play a vital role in your vehicle’s safety systems by ensuring reliable sensor integration. They connect sensors that detect crashes, enabling quick responses from safety features like airbags and anti-lock brakes. Properly designed and maintained harnesses prevent electrical failures and signal disruptions, enhancing crash safety. When harnesses are secure and well-inspected, your vehicle’s safety systems work seamlessly, giving you peace of mind on every drive.

What Are the Latest Innovations in Automotive Cable Harness Manufacturing?

You’ll find that the latest innovations in automotive cable harness manufacturing focus on smart manufacturing and wireless integration. Advanced techniques like automation and robotics streamline production, increasing precision and reducing errors. Wireless integration allows for more flexible wiring solutions, minimizing physical connections and enhancing vehicle design. These innovations help you build safer, more reliable, and efficient cable harnesses, ultimately improving overall vehicle performance and user experience.

How Do Environmental Factors Affect Cable Harness Durability?

Environmental factors critically impact your cable harness durability. Exposure to moisture and corrosive elements can cause corrosion, compromising connections and performance. UV rays weaken materials over time, reducing UV stability and leading to cracks or brittleness. To protect your harness, guarantee it has corrosion resistance coatings and UV-stable insulation. Regular inspections and proper sealing can also extend its lifespan, keeping your automotive network reliable even in harsh conditions.

What Are Common Troubleshooting Methods for Harness-Related Issues?

Did you know that wiring issues account for nearly 30% of automotive electrical problems? When troubleshooting harness-related issues, you should start with diagnostic techniques like multimeter tests and circuit analysis. Conduct thorough wiring inspections to identify broken or loose connections, corrosion, or damaged insulation. These steps help pinpoint faults quickly, saving you time and preventing further damage. Always guarantee your tools are calibrated and follow manufacturer guidelines for accurate results.

How Is Electromagnetic Interference Minimized in Automotive Harnesses?

You minimize electromagnetic interference in automotive harnesses by incorporating electromagnetic shielding, which blocks external signals from disrupting the cables. Using grounded shields and proper routing also helps maintain signal integrity. Keep cables away from high-power components and use twisted pairs for sensitive signals. Proper shielding and careful routing guarantee your harnesses resist interference, preserving signal quality and preventing data errors that could impact vehicle performance.

Conclusion

In your automotive adventure, cable harnesses carry crucial currents with confidence and clarity. By bundling, protecting, and balancing the network, they bolster vehicle safety and sustain seamless signals. Understanding their significance helps you appreciate the intricate infrastructure behind every drive. So, stay savvy about these silent saviors, ensuring your vehicle’s vitality and value. With well-woven wiring, you’ll wander worry-free, knowing your car’s core connections are consistently secure and strong.