A cable spline helps you organize and secure UTP cables, keeping them neat and preventing tangling or damage. It gently grips cables with ridges or channels, ensuring they stay in place without harm. Made from durable plastics, spline materials withstand environmental factors, providing long-lasting support. Proper use of cable splines reduces signal issues and physical wear. To discover how these components improve cable management and protection, keep exploring their role and benefits.

Key Takeaways

- Cable spline securely holds UTP cables together, preventing tangling and maintaining organized cable runs.

- It protects cables from physical damage and strain, ensuring signal integrity and longevity.

- Made from durable plastics like nylon, it resists environmental factors such as UV, moisture, and temperature changes.

- Features ridges or channels to grip cables gently yet firmly, accommodating various cable diameters.

- Easily installed using snap-fit or screw-fastening designs for reliable and reusable cable management.

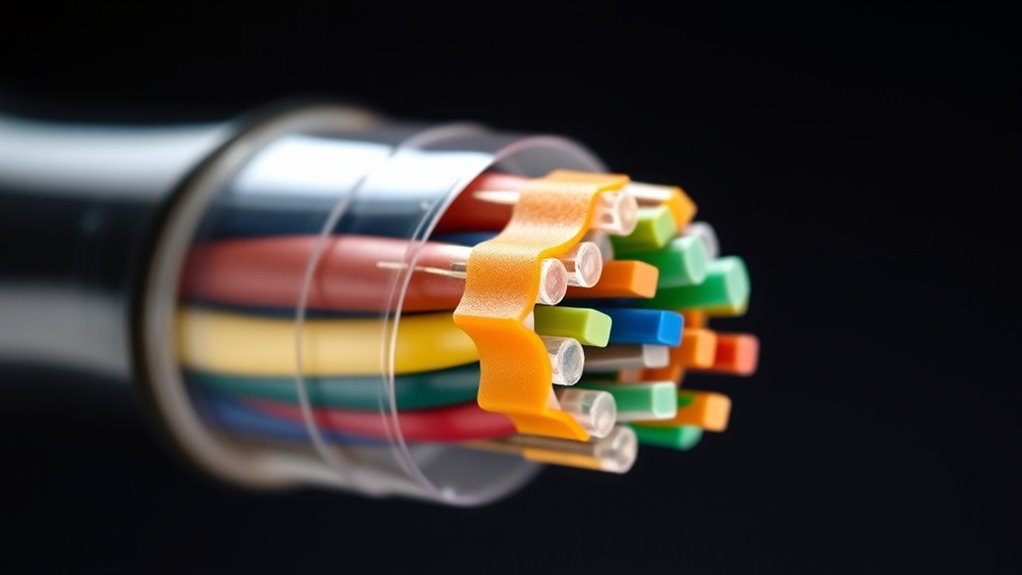

A cable spline is a versatile fastening component used to securely attach cables, wires, or hoses to various surfaces or structures. When it comes to UTP (Unshielded Twisted Pair) cables, cable splines play a crucial role in maintaining organization and guaranteeing the integrity of the network setup. During cable spline manufacturing, precision is key. Manufacturers select specific cable spline materials designed to withstand environmental factors, such as UV exposure, moisture, and temperature fluctuations. These materials often include durable plastics like nylon or polyethylene, which provide strength without adding unnecessary weight or bulk. The choice of cable spline materials directly impacts the longevity and performance of the fastening system, making it essential to select high-quality options suited for your application.

Cable splines securely organize UTP cables using durable, environmentally resistant materials like nylon or polyethylene for lasting performance.

In practical use, the purpose of a cable spline is to hold multiple cables neatly together, preventing tangling and reducing strain on individual wires. This is especially important in network environments where cable management is critical to guarantee signal quality and ease of maintenance. The spline’s design typically features ridges or channels that grip the cables firmly yet gently, avoiding damage while providing a secure hold. When attaching UTP cables, using the right cable spline materials ensures that the spline maintains its shape and grip over time, even in demanding conditions. This durability minimizes the need for frequent adjustments or replacements, saving you time and effort.

The manufacturing process also influences how well the cable spline performs. During cable spline manufacturing, attention is paid to the tolerances and flexibility of the spline, so it fits various cable diameters without slipping or causing damage. Manufacturers often incorporate features like snap-fit or screw-fastening options, making installation straightforward and reliable. By selecting appropriate cable spline materials, manufacturers can produce splines that resist cracking or deformation, even after repeated use or exposure to harsh environments. This resilience is vital in maintaining a clean, organized cable setup, whether in data centers, industrial settings, or residential installations. Additionally, material selection plays a significant role in the spline’s ability to withstand environmental stressors, ensuring long-term performance.

Ultimately, understanding the importance of cable spline manufacturing and the selection of suitable materials helps you choose the right fastening component for your needs. Properly manufactured cable splines made from high-quality materials ensure your cables remain organized, protected, and functional over time. They help prevent problems caused by loose or tangled wiring, which can lead to signal interference or physical damage. With the right cable spline in place, you can confidently manage your cables, knowing they’re securely fastened and less vulnerable to environmental stressors.

PETECHTOOL RJ45 CAT6 Connector End Pass Through Ethernet Cat6 Ends 8P8C Modular Plug for Solid or Stranded UTP Ethernet Cable ( 100 Packs – with Wire Stripper

✅RJ45 CAT5/6 CONNECTORS not only let you make enternet cables in custom lenths without breaking the bank,but also…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Does a Cable Spline Affect Signal Integrity?

A cable spline improves signal integrity by reducing electromagnetic interference and signal attenuation. When you use a spline, it acts as a barrier that minimizes crosstalk between pairs, ensuring clearer data transmission. This helps maintain consistent signal strength and quality, especially over longer distances. By controlling interference, a spline allows your UTP cables to deliver better performance, keeping your network faster and more reliable.

Can Cable Splines Be Reused or Recycled?

You can often reuse cable splines if they’re still in good condition, but recycling potential varies. Reuse feasibility depends on their physical state—if undamaged, you might reuse them in other cables. However, many splines aren’t designed for multiple uses, and recycling options may be limited due to material type. Check local recycling programs, as some may accept splines made from recyclable plastics, helping reduce waste and support sustainability efforts.

Are Cable Splines Compatible With All UTP Cable Types?

Think of cable splines as universal keys for UTP cables. They work with most cable spline materials, but not all, depending on the cable’s construction. Your success depends on spline installation techniques and the spline’s compatibility with specific cable types. Always check manufacturer specifications to verify that the spline material matches your UTP cable’s design, so the connection remains secure and reliable across different cable types.

What Are Common Installation Challenges With Cable Splines?

You might face installation challenges with cable splines, especially if you don’t follow proper procedures. Difficulties often arise from improper handling or bending, which can damage the spline or cable. Confirming material durability is key; using splines made from sturdy materials helps prevent breakage during installation. Carefully follow installation procedures, avoid excessive force, and check compatibility to minimize issues and ensure a secure, reliable cable setup.

Do Cable Splines Influence Cable Flexibility?

Cable spline design can influence cable flexibility, but the impact is usually minimal. If the spline is stiff or bulky, it might reduce the cable’s bendability, making installation trickier in tight spaces. However, many modern splines are designed to balance structural support with flexibility, so you generally won’t notice a significant difference. When choosing a cable, consider the spline’s design if flexibility is essential for your installation needs.

Sohalejr 250 Pack Zip Ties 8 inch Clear Cable Tie Wraps 50 lbs Tensile Strength self-locking Fastener 3.6 mm width Wire Ties for Organization and Management of Electrical Cords, Plants, and Fences

0.02 oz Weight Ties: Lightweight but toughly made for daily use. With 3.6 mm Width, it’s enough to…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Understanding the purpose of a cable spline helps you appreciate its role in UTP cables. It guarantees signal integrity and reduces crosstalk, making your network more reliable. Notably, studies show that proper cable construction can improve data transmission speeds by up to 30%. So, next time you set up or troubleshoot your network, remember that the cable spline is a small but essential component working behind the scenes to keep your connection steady and fast.

Cable organizer spline with ridges

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Reusable cable spline for network cables

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.