Maintaining clean fiber connectors is vital for ensuring peak network performance and avoiding costly repairs. Regular inspections with fiber optic scopes can help you catch dirt, scratches, or damage early, while proper cleaning techniques prevent contaminants from affecting signal quality. If you neglect these steps, you risk increased errors and reduced lifespan of your cables. Staying proactive with your maintenance routine can save time and money—so, understanding the best practices becomes essential.

Key Takeaways

- Regularly inspect fiber connectors with proper scopes to detect dirt, scratches, or damage early.

- Use specialized, lint-free cleaning tools like wipes, pens, or compressed air to remove dust and debris gently.

- Always clean connectors before mating or disconnecting to maintain optimal signal quality.

- Follow manufacturer guidelines for cleaning procedures and avoid household cleaners or rough materials.

- Routine maintenance prevents signal loss, reduces downtime, and prolongs the lifespan of fiber optic cables.

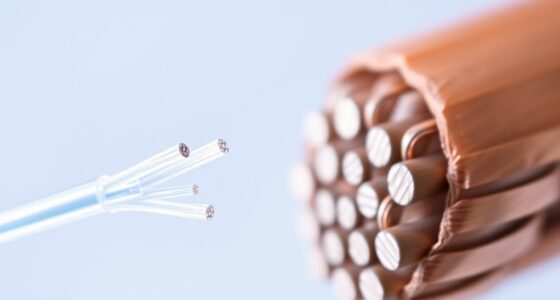

Proper cleaning and maintenance of fiber connectors are essential to guarantee peak performance and prevent signal loss. When you handle fiber connections regularly, paying close attention to connector inspection and dust removal becomes critical. Over time, dust, dirt, and other contaminants can accumulate on the connector end faces, impairing the quality of your signal. These particles can cause increased insertion loss, reflection, or even damage to the delicate fiber surfaces if not addressed promptly.

The first step is to thoroughly inspect your connectors before and after installation or maintenance. Use a fiber optic inspection scope to look for dirt, scratches, or any damage on the connector end face. If you notice any contamination, don’t just wipe it away with a cloth—this can sometimes cause more scratches or push debris further into the connector. Instead, rely on proper cleaning methods designed specifically for fiber optics. Regular inspection helps you identify issues early, ensuring your system remains reliable and efficient.

Dust removal is one of the most straightforward yet crucial parts of connector maintenance. Dust and other particles are the primary culprits behind signal degradation. To effectively remove dust, you should use specialized cleaning tools like lint-free wipes, fiber optic cleaning pens, or compressed air designed for optical components. When cleaning, avoid using rough materials or household cleaners, as these can scratch or damage the connector end face. Instead, gently wipe or blow away dust, making sure to hold the connector securely so you don’t accidentally bend or damage the fiber.

Remember, always clean the connector before mating or disconnecting it to prevent transferring contaminants. When using a cleaning wipe or pen, follow the manufacturer’s instructions carefully, applying a gentle, even motion. For stubborn debris, you might need to repeat the cleaning process or use a cleaning cassette if you’re working with multiple connectors. Always ensure the cleaning tools are free from lint or other residues that could transfer onto the connector.

Consistent connector inspection and dust removal not only extend the lifespan of your fiber optic cables but also help maintain ideal signal integrity. Neglecting these steps can lead to increased attenuation, higher error rates, and costly system downtime. By adopting a routine of careful inspection and proper cleaning, you ensure your fiber network performs at its best, providing reliable and high-quality data transmission for your needs. In the end, taking a few extra moments for proper maintenance saves you time, money, and headaches down the road. Additionally, implementing applicable cleaning techniques can further optimize your fiber optic performance.

Frequently Asked Questions

How Often Should Fiber Connectors Be Inspected for Cleanliness?

You should inspect your fiber connectors at least monthly to guarantee cleanliness and prevent contamination risks. Regular inspections help you catch dirt, dust, or other debris before they cause signal loss or damage. If you notice any contamination, clean the connectors promptly. Increased inspection frequency is necessary in dusty or harsh environments. Staying vigilant with your inspection routine keeps your fiber connections reliable and maintains peak performance.

Are There Eco-Friendly Cleaning Options for Fiber Connectors?

Cleaning fiber connectors is like tending to a delicate garden—you want eco-friendly options. You can use biodegradable cleaning wipes or plant-based cleaning solutions, which are gentle on the environment yet effective. These options reduce your ecological footprint and keep your connectors pristine without harmful chemicals. Always ensure you’re following manufacturer instructions for ideal results, and you’ll maintain both your equipment and the planet’s health.

Can Improper Cleaning Damage Fiber Connectors?

Yes, improper cleaning techniques can cause connector damage. Using harsh chemicals or abrasive materials might scratch or degrade the fiber surface, leading to poor performance or failure. You should always follow proper cleaning methods, such as using lint-free wipes and recommended cleaning solutions. Gentle, precise cleaning helps prevent connector damage, ensuring reliable connections and extending the lifespan of your fiber optics.

What Tools Are Essential for Fiber Connector Maintenance?

You need essential tools like a fiber connector cleaner, inspection microscope, and a connector polishing kit for maintenance. These tools help you perform fiber connector diagnostics and guarantee peak performance. Use the inspection microscope to check for dirt or damage, while the polishing kit helps you refine connector ends with proper polishing techniques. Regularly maintaining your connectors with these tools prevents signal loss and extends their lifespan.

How Do Temperature Changes Affect Fiber Connector Cleanliness?

Temperature changes can impact fiber connector cleanliness by causing thermal expansion, which leads to tiny gaps or misalignments. These shifts can allow dust and debris to settle more easily, compromising connector integrity. As temperatures fluctuate, you should regularly inspect and clean your connectors to prevent contamination. Maintaining a stable environment minimizes thermal expansion effects, ensuring your connectors stay clean and perform efficiently, reducing connection issues and prolonging their lifespan.

Conclusion

Regularly cleaning your fiber connectors guarantees reliable performance and prevents costly downtime. For instance, imagine a data center that faced frequent signal issues until technicians adopted a strict cleaning routine. After using lint-free wipes and inspecting connectors with a fiber optic scope, they saw a significant reduction in errors. By maintaining proper cleaning habits, you’ll extend your cables’ lifespan and keep your network running smoothly—making sure your connections stay clean and efficient every time.