To terminate fiber optic cables with MPO/MTP connectors, start by cleaning the connector end-face with a lint-free wipe and alcohol to remove dirt and oil. Carefully align the fibers during termination, avoiding bending or damaging the ferrule. Confirm the connector is properly inserted into the port, checking for secure fit. Always inspect the finished end-face with a visual fault locator or test equipment. Following these steps helps ensure high-quality, reliable connections—continue to explore detailed procedures for perfect results.

Key Takeaways

- Prepare and strip the fiber, then cleave it to a precise, smooth end-face for optimal termination.

- Use a proper MPO/MTP connector or cassette aligned with the fiber type and specifications.

- Gently insert the cleaved fiber into the MPO/MTP connector, ensuring correct orientation and full engagement.

- Perform cleaning of the connector end-face before and after termination to prevent contamination.

- Inspect the terminated connector with a magnifier or test equipment to verify quality and alignment.

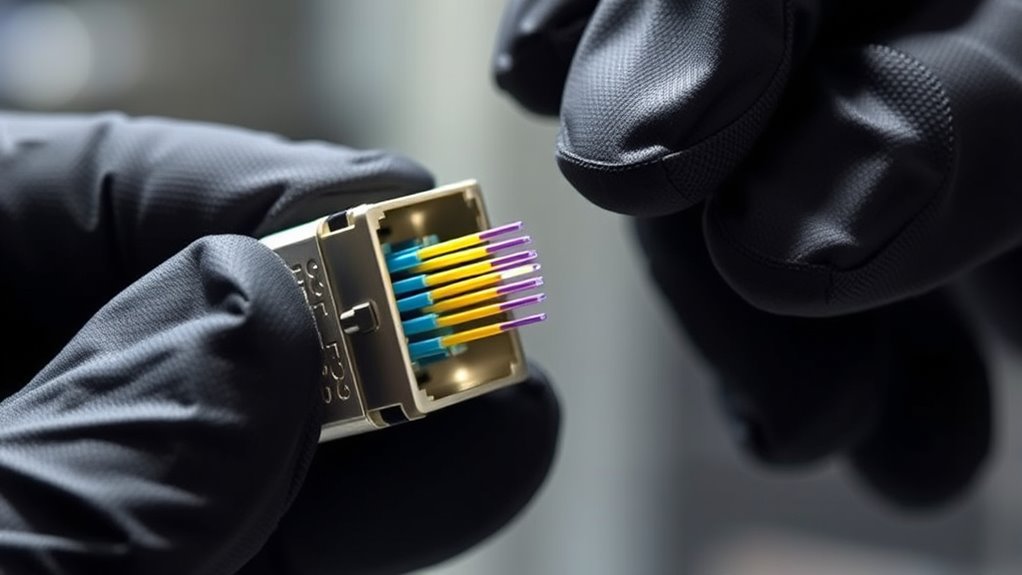

Are you wondering how to properly terminate fiber optic cables? It’s crucial to understand the different connector types, especially when working with MPO/MTP connectors, which are popular for high-density applications. These connectors are designed for quick, reliable connections, but they require precise handling and proper cleaning procedures to guarantee peak performance. First, familiarize yourself with the connector types involved. MPO (Multi-fiber Push On) and MTP (a brand of MPO) connectors feature multiple fibers housed in a single rectangular ferrule, making them ideal for data centers and high-speed networks. Knowing the specifics of these connectors helps you handle them correctly and avoid damaging the delicate fibers during termination.

When terminating with MPO/MTP connectors, the key step is guaranteeing that the connectors are clean. Contaminants like dust, oil, or residue can markedly impair signal quality, leading to high insertion loss and poor network performance. To prevent this, always follow strict cleaning procedures before and after termination. Start by inspecting the connector end-face with a magnifying device to check for dirt or scratches. Use a lint-free, alcohol-moistened swab or a specialized fiber optic cleaning wipe to gently clean the connector end-face. For stubborn dirt, a specialized fiber optic cleaning solution can be used—just apply a small amount to the cleaning wipe and gently wipe the surface. Avoid touching the connector end-face with your fingers, as oils from your skin can cause contamination. Additionally, proper fiber alignment during insertion is essential to ensure optimal connection quality.

During the termination process, handle the MPO/MTP connector with care to avoid scratching or damaging the ferrule. When inserting the fiber into the connector, make sure it aligns properly to prevent bending or breaking the fibers. Once connected, always perform a thorough cleaning of the connector before mating it with the port. This ensures that no debris is transferred and maintains the integrity of the connection. After termination, re-inspect the connector with a visual fault locator or test equipment to confirm cleanliness and proper alignment.

Frequently Asked Questions

What Tools Are Essential for Mpo/Mtp Termination?

You need vital tools like a fiber cleaver for precise cuts and a polishing puck for fiber polishing. A connector cleaning kit guarantees your MPO/MTP connectors stay free of dirt and debris, which is essential for peak performance. Don’t forget a precision stripper and crimp tools, as well as a visual fault locator. These tools help you achieve clean, reliable terminations by guaranteeing proper fiber polishing and connector cleaning, reducing signal loss.

How Do I Troubleshoot Common Mpo/Mtp Termination Issues?

Did you know that improper MPO/MTP termination causes up to 30% of connection failures? To troubleshoot, first check for connector polishing issues; smooth, clean ends ensure ideal signal. Next, inspect cable management—bends or twists can disrupt connections. Use a visual fault locator to identify breaks or misalignments. Properly maintaining connector polish and cable routing helps prevent common MPO/MTP termination problems and guarantees reliable high-speed data transfer.

Can Mpo/Mtp Connectors Be Reused After Termination?

MPO/MTP connectors can sometimes be reused, but it depends on the connector reusability and whether the termination integrity remains intact. If the connector shows no signs of damage or contamination, you might reuse it, but keep in mind that repeated terminations can degrade performance. To guarantee ideal signal quality, it’s best to carefully inspect each connector and prioritize new terminations when maintaining high-quality fiber optic connections.

What Are the Safety Precautions During Mpo/Mtp Termination?

Like a vigilant guardian, you must prioritize safety during MPO/MTP termination. Always inspect connectors thoroughly to spot any flaws, and don your safety gear—gloves, eye protection, and a mask—to shield yourself from fiber shards and dust. Keep your workspace clean, and handle connectors with care. Remember, staying alert and cautious transforms a potentially hazardous task into a smooth, successful operation, protecting both your health and equipment integrity.

How Does Connector Cleanliness Affect Mpo/Mtp Performance?

Connector cleanliness directly impacts your MPO/MTP performance by preventing signal loss and guaranteeing ideal data transmission. When you maintain proper connector cleanliness standards, you reduce contamination like dust, dirt, and oils that cause poor contact. Regular connector maintenance, including cleaning with appropriate tools and methods, keeps your connectors free of debris. This practice ensures reliable connections, minimizes outages, and preserves the integrity of your fiber optic network over time.

Conclusion

Terminating fiber optic cables with MPO/MTP connectors may seem intimidating, but with the right techniques, you can do it confidently. Remember, properly terminated cables guarantee peak performance and longevity of your network. Did you know that poor termination accounts for nearly 60% of fiber optic connection failures? Taking the time to learn and perfect your termination skills not only saves you money but also keeps your network running smoothly and reliably.