When choosing cable jacket materials, you’ll want to focus on durability, flexibility, and fire safety. Common options like PVC, polyethylene, and LSZH are designed to meet specific fire safety standards by reducing flame spread and smoke emission. Fire-resistant and flame-retardant jackets help prevent fire from spreading, while standards like UL and IEC guarantee safety performance. To learn more about how these materials and standards work together to protect your systems, keep exploring the details below.

Key Takeaways

- Cable jackets are made from materials like PVC, polyethylene, XLPE, and silicone, each offering different fire resistance and durability levels.

- Fire safety standards (e.g., UL 1685, IEC 60332-3) specify flammability, smoke emission, and toxicity criteria for cable jackets.

- Fire-resistant and flame-retardant jackets help prevent fire spread, ensuring compliance with safety regulations.

- LSZH (Low Smoke Zero Halogen) materials reduce toxic smoke, enhancing safety in enclosed environments during fires.

- Testing methods include flame spread, heat release, and smoke toxicity assessments to verify compliance and safety performance.

Common Cable Jacket Materials and Their Properties

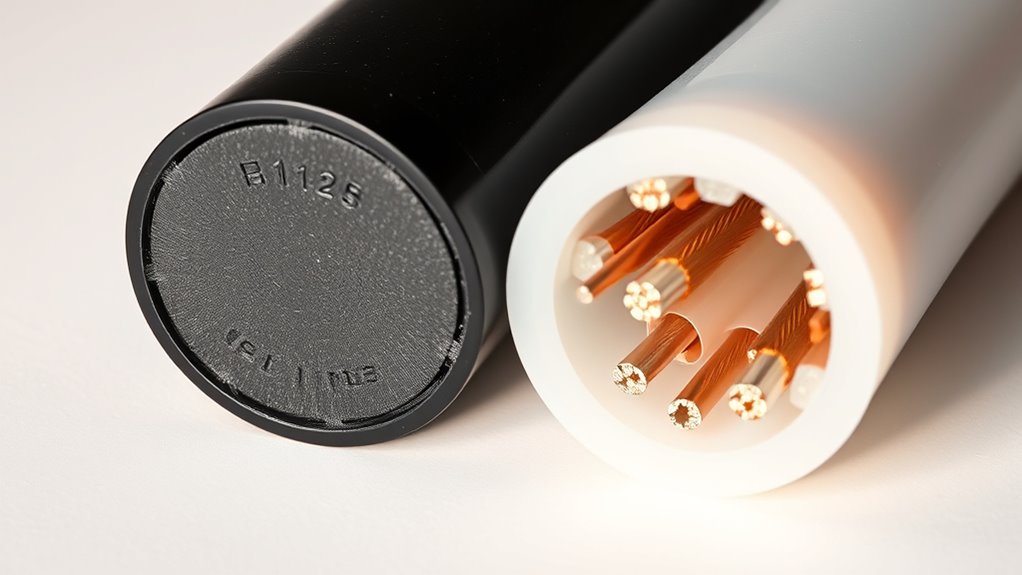

When choosing cable jacket materials, understanding their properties is essential for guaranteeing safety and performance. For fiber optic cables, jackets often use durable plastics like PVC or polyethylene, which protect delicate fibers from physical damage and environmental factors. Rubber coatings are also common, offering flexibility, impact resistance, and weatherproofing, especially in outdoor or industrial settings. These rubber coatings help prevent cracks and tears, maintaining the cable’s integrity over time. In contrast, fiber optic cables require jackets that prevent signal interference and minimize attenuation. Knowing the specific properties of each material allows you to select the right jacket type for your application, balancing durability, flexibility, and safety. Properly chosen materials ensure reliable performance and compliance with safety standards. Additionally, selecting materials with fire safety standards in mind is crucial to reduce the risk of fire hazards in various environments. Considering how different materials perform under temperature extremes can further improve safety and reliability in challenging conditions.

Fire-Resistant and Flame-Retardant Cable Jackets

Choosing the right cable jacket material isn’t just about durability and flexibility; fire safety plays an essential role, especially in environments where fire risks are high. Fire-resistant and flame-retardant cable jackets help prevent the spread of flames, giving you more time to respond during emergencies. These jackets enhance cable insulation by maintaining their protective properties even under extreme heat, reducing the risk of failure. They also improve jacket durability, ensuring that cables withstand exposure to heat and flames without degrading quickly. Using materials like flame-retardant polyolefins or fire-retardant thermoplastics ensures your cables remain safer in fire-prone settings. Additionally, understanding the refrigeration cycle can help in designing systems that are both efficient and safe under emergency conditions. Incorporating fire safety standards into your material selection process ensures compliance and optimal protection. Ultimately, selecting fire-resistant jackets helps protect lives, property, and vital infrastructure by minimizing fire hazards and maintaining cable integrity during emergencies.

Standards for Fire Safety in Cable Manufacturing

Ensuring fire safety in cable manufacturing requires strict adherence to established standards that specify performance criteria and testing protocols. These standards guarantee that cable insulation materials can withstand fire exposure without compromising safety. They set limits on the flammability, smoke emission, and toxicity of cable jackets and insulation. Additionally, standards address electrical conductivity, ensuring that cables maintain proper conductivity during and after exposure to fire, preventing electrical failures. Testing methods include flame spread tests, heat release measurements, and smoke toxicity assessments. Compliance guarantees that cables are designed to minimize fire hazards, reduce smoke production, and maintain electrical integrity under fire conditions. Ulta Beauty Store Hours To meet these standards, manufacturers often incorporate fire-resistant materials that are tested under strict laboratory conditions. Understanding fire safety standards is crucial for selecting appropriate cable materials and ensuring overall safety compliance in various applications. Furthermore, ongoing research and updates to these standards help improve fire safety performance and adapt to emerging risks and technologies.

The Role of Low Smoke Zero Halogen (LSZH) Materials

Low Smoke Zero Halogen (LSZH) materials play an essential role in enhancing fire safety, especially in enclosed or confined spaces. These materials emit minimal smoke and no halogen gases when exposed to fire, reducing toxic fumes and improving visibility during evacuations. Their use is critical in environments like data centers, hospitals, and transportation systems, where air quality and safety are paramount. Additionally, LSZH cables maintain excellent material durability, ensuring that cables withstand mechanical stresses and environmental conditions over time. This fire safety benefit is further supported by their resistance to environmental factors, which helps maintain safety standards over the lifespan of the cables. Moreover, the incorporation of biodiversity concepts in material design can lead to more sustainable and environmentally friendly cable solutions. This combination of fire safety benefits and durability makes LSZH materials a preferred choice for many applications. By choosing LSZH jackets, you help minimize fire hazards, protect occupants, and comply with strict safety standards. Their reliability is essential in safeguarding lives and infrastructure during emergencies. Incorporating fire-resistant materials into cable jackets further enhances safety, especially in high-risk environments. Furthermore, ongoing research into sustainable materials aims to improve the environmental footprint of these safety components.

Testing Methods for Fire Performance of Cable Jackets

You need to understand how flammability testing procedures evaluate cable jackets’ fire resistance. Standardized fire ratings help compare materials consistently, but real-world conditions can differ from lab results. Recognizing the differences between laboratory tests and actual fire scenarios is essential for ensuring safety. Additionally, understanding fire safety standards can guide the selection of appropriate materials for specific applications.

Flammability Testing Procedures

How do manufacturers determine if a cable jacket meets fire safety standards? They conduct specific flammability testing procedures that simulate real fire conditions. These tests evaluate how quickly a cable jacket ignites, how much flames spread, and the amount of smoke produced. The results help ensure the jacket’s fire performance aligns with safety regulations. During testing, manufacturers consider factors like cable jacket aesthetics, since visual appearance can influence material choices, and manufacturing cost, as more fire-resistant materials may raise expenses. The procedures involve standardized methods such as flame ignition, burn rate measurement, and smoke density analysis. These tests provide critical data, guiding product development and certification, ensuring cables provide necessary fire safety without compromising performance or aesthetics. Additionally, testing methods are continually refined to reflect evolving fire safety standards and real-world scenarios, incorporating advancements in flammability testing technology to improve accuracy and reliability. Moreover, these procedures often include fire safety standards compliance checks to guarantee that cable jackets meet regional and international regulations. It is essential that industry stakeholders stay informed about testing procedures to ensure compliance and enhance overall safety.

Standardized Fire Ratings

Standardized fire ratings provide a clear benchmark for evaluating a cable jacket’s fire performance according to industry safety standards. These ratings assess how well a jacket resists ignition, smoke emission, and flame spread during testing. They help ensure cable jacket durability and safety, especially in complex installation techniques. The testing methods include various protocols that simulate real fire scenarios, ensuring consistency across products. Here’s a quick overview:

| Rating System | Test Duration | Key Focus |

|---|---|---|

| UL 1685 | 15 minutes | Flame spread and smoke |

| IEC 60332-3 | 30 seconds | Flame propagation |

| ANSI/IEEE 383 | 20 minutes | Flame retardance |

| ASTM E84 | 10 minutes | Surface burning characteristics |

These standards guide manufacturers and installers to select jackets that meet safety requirements, balancing fire performance with durability.

Laboratory vs. Real-World Tests

Laboratory tests are designed to evaluate the fire performance of cable jackets under controlled, repeatable conditions, providing a baseline for safety standards. These tests help you understand material durability and how jackets respond to fire exposure in ideal settings. However, real-world environments often introduce variables like airflow, temperature fluctuations, and physical wear that lab tests can’t fully replicate. As a result, the fire safety of cable jackets in actual use may differ from laboratory results. You need to take into account both testing methods to ensure comprehensive safety assessments. While lab tests offer consistency and baseline data, real-world testing accounts for practical challenges and helps verify material durability over time. Combining both approaches ensures a more accurate understanding of a cable jacket’s fire safety performance.

Regulatory Compliance and Certification Processes

Navigating regulatory compliance and certification processes is essential to guarantee your cables meet fire safety standards. You need to understand the specific certifications required for your target markets, such as UL or IEC standards. During this process, you’ll evaluate how cable jacket aesthetics influence compliance, as certain materials may be preferred or mandated for fire safety reasons. Conducting a thorough manufacturing cost analysis helps you balance safety features with production expenses, guaranteeing your cables remain competitive. Certification involves testing for flame retardance, smoke production, and other safety parameters. Keep detailed documentation of your materials and manufacturing practices to facilitate inspections. Staying current with evolving regulations makes certain your products maintain compliance, reducing the risk of costly recalls or market restrictions. Transparency in compliance and certification details, including regulatory disclosures, can enhance consumer trust and market acceptance. Engaging with fire safety standards experts can provide valuable insights to ensure comprehensive compliance. Furthermore, understanding the self-understanding of your product’s safety features can help in aligning your manufacturing processes with regulatory expectations. Regularly reviewing fire safety standards updates ensures your products adapt to new safety requirements and maintain their certifications.

Comparing Polyvinyl Chloride (PVC) and Polyethylene (PE) Jackets

When comparing PVC and PE jackets, you’ll want to contemplate their fire retardant properties and environmental impacts. PVC generally offers better fire resistance, but it’s often more harmful to the environment during production and disposal. Understanding these differences helps you choose the best material for safety and sustainability. Additionally, considering the fire safety standards applicable to these materials ensures compliance and optimal protection. As AI advancements continue to influence safety regulations, staying informed about AI-driven safety measures can further enhance material safety assessments.

Fire Retardant Properties

Polyvinyl chloride (PVC) and polyethylene (PE) jackets differ profoundly in their fire retardant properties, which directly impact cable safety and compliance with fire safety standards. PVC inherently contains flame-retardant additives, making it more resistant to ignition and slow to propagate flames, enhancing cable insulation safety. In contrast, standard PE jackets are highly combustible, igniting easily and allowing flames to spread quickly, which can compromise safety. To meet fire safety requirements, PE often needs additional flame-retardant treatments, affecting jacket durability over time. PVC’s superior fire resistance helps prevent fires from spreading, safeguarding both infrastructure and occupants. Your choice of jacket influences not just cable performance but also the overall fire safety of the installation.

Environmental Impact

Environmental considerations are a key factor when choosing cable jacket materials, as PVC and polyethylene (PE) have distinct ecological footprints. PVC often poses challenges in recycling practices due to its chlorine content, which can release harmful substances if not processed properly. Its ecological footprint is higher because of the energy-intensive manufacturing process and difficult disposal. In contrast, polyethylene is easier to recycle and generally has a lower ecological footprint, making it a more environmentally friendly option. PE jackets can be melted down and reused with minimal environmental impact, reducing waste. When evaluating environmental impact, you should consider the entire lifecycle of the material—from production to disposal—to make a responsible choice aligned with sustainability goals.

Advances in Fire-Resistant Cable Technologies

Recent advances in fire-resistant cable technologies have considerably enhanced safety standards by developing materials that can withstand high temperatures and prevent the spread of flames. You’ll find that modern cable insulation now incorporates fire-retardant compounds, substantially reducing flammability. These innovations often involve specialized polymeric materials that maintain integrity during fires, limiting smoke and toxic fumes. Conductor materials have also improved, with some cables using metal alloys or coatings that resist heat and prevent melting or failure under extreme conditions. These technological improvements guarantee cables retain their functionality longer during fires, providing essential safety margins. By combining enhanced cable insulation with robust conductor materials, manufacturers are better equipped to produce fire-resistant cables that meet stringent safety standards, safeguarding people and property more effectively.

Impact of Material Selection on Safety and Maintenance

The choice of cable jacket materials directly influences both safety and maintenance requirements. Durable materials reduce the risk of damage, minimizing repairs and replacements, and ensuring safer operation over time. Cost considerations are vital; investing in higher-quality jackets might seem expensive initially but can save money long-term through fewer maintenance needs. Conversely, cheaper options may compromise safety and increase ongoing costs. Consider this table:

| Material Type | Material Durability | Cost Considerations |

|---|---|---|

| PVC | Moderate | Low upfront, higher long-term costs |

| XLPE | High | Moderate, durable choice |

| Silicone | Very high | Higher initial investment |

Choosing the right jacket affects safety, maintenance ease, and overall reliability—making it a decision that impacts your entire system.

Global Variations in Fire Safety Standards for Cables

As cable jacket materials are selected for safety and durability, understanding the variations in fire safety standards across different regions becomes equally important. Different countries enforce distinct regulations, influencing cable design, jacket manufacturing processes, and fire-resistant properties. For example, some regions require specific fire safety ratings, affecting choices in cable color coding to identify fire-resistant cables easily. These standards impact how jackets are manufactured, with stricter regulations demanding advanced materials that resist ignition and limit smoke. Recognizing these regional differences helps you ensure compliance and safety in your installations. Staying informed about local standards allows you to select cables that meet specific fire safety criteria, reducing risks and enhancing overall system safety. This global perspective ensures your projects adhere to the appropriate requirements everywhere they’re deployed.

Frequently Asked Questions

How Do Cable Jacket Materials Impact Overall Building Fire Safety?

Your choice of cable jacket materials directly impacts building fire safety. Durable insulation helps prevent damage and maintains safety over time, while low-flammability materials reduce fire risks. If you select jackets with high flammability, they can contribute to faster fire spread and increased smoke production, endangering occupants. Opt for fire-resistant, durable materials to enhance overall safety, minimize hazards, and guarantee compliance with safety standards.

Are There Eco-Friendly Fire-Resistant Cable Jacket Options Available?

Yes, eco-friendly fire-resistant cable jacket options are available, acting like a green shield for your building. You can choose jackets made from biodegradable polymers or recycled materials that meet fire safety standards. These options help reduce environmental impact while maintaining safety. By selecting eco-conscious materials, you’re not only protecting your space but also contributing to a healthier planet, proving that safety and sustainability can go hand in hand.

How Does Cable Jacket Material Influence Smoke Toxicity During a Fire?

Your cable jacket material directly impacts smoke toxicity during a fire, affecting your safety. Some materials produce more toxic emissions, increasing risks of smoke inhalation. For example, PVC jackets release harmful chemicals, while eco-friendly options like certain thermoplastics emit fewer toxic fumes. Choosing the right jacket material helps reduce toxic emissions, minimizing smoke inhalation hazards and enhancing overall fire safety for you and others around you.

What Are the Cost Differences Between Fire-Retardant and Standard Jackets?

Imagine saving thousands just by choosing the right cable jacket! Fire-retardant jackets typically cost 30-50% more than standard ones, but their superior material durability and enhanced safety can justify the extra expense. Our pricing analysis shows that investing in fire-retardant jackets reduces long-term fire risks and potential damage costs. So, while they may seem pricier upfront, their safety benefits make them a smart, cost-effective choice in the long run.

How Do Climate Conditions Affect Cable Jacket Fire Safety Performance?

Climate conditions critically impact cable jacket fire safety performance. You’ll find that climate-induced material degradation weakens jackets over time, reducing their fire resistance. Extreme temperatures, moisture, and UV exposure accelerate aging, compromising safety and increasing environmental impact of jackets. To guarantee reliable performance, you should select jacket materials designed for your specific climate, which can help mitigate degradation and maintain fire safety standards throughout their lifespan.

Conclusion

You might think all cable jackets offer the same fire safety, but material choice truly matters. Selecting fire-resistant or LSZH jackets can markedly reduce fire hazards and toxic smoke. While standards vary worldwide, adhering to proven safety protocols ensures your installations remain secure. Trust the science—using the right materials isn’t just about compliance, it’s about protecting lives and property from preventable fire risks. Prioritize safety; it’s a decision that pays off in the long run.