Temperature impacts your cable performance in several ways. When it rises, it causes atoms to vibrate more, increasing resistance and reducing conductivity, which can lead to overheating. High heat also degrades insulation, speeds up chemical breakdown, and causes expansion stresses, risking damage. Cold temperatures make cables brittle and less flexible, increasing the likelihood of fractures. Proper thermal management and material choices help minimize these effects, so exploring further reveals how to guarantee cables stay reliable over time.

Key Takeaways

- Elevated temperatures increase electrical resistance, reducing conductivity and potentially causing power losses and overheating.

- High heat accelerates polymer degradation, leading to insulation brittleness, cracks, and decreased lifespan.

- Temperature fluctuations cause expansion and contraction, generating mechanical stresses that can damage cables.

- Proper thermal management and material selection help maintain performance and prevent thermal-related failures.

- Moisture ingress at high temperatures promotes insulation deterioration, swelling, and potential electrical faults.

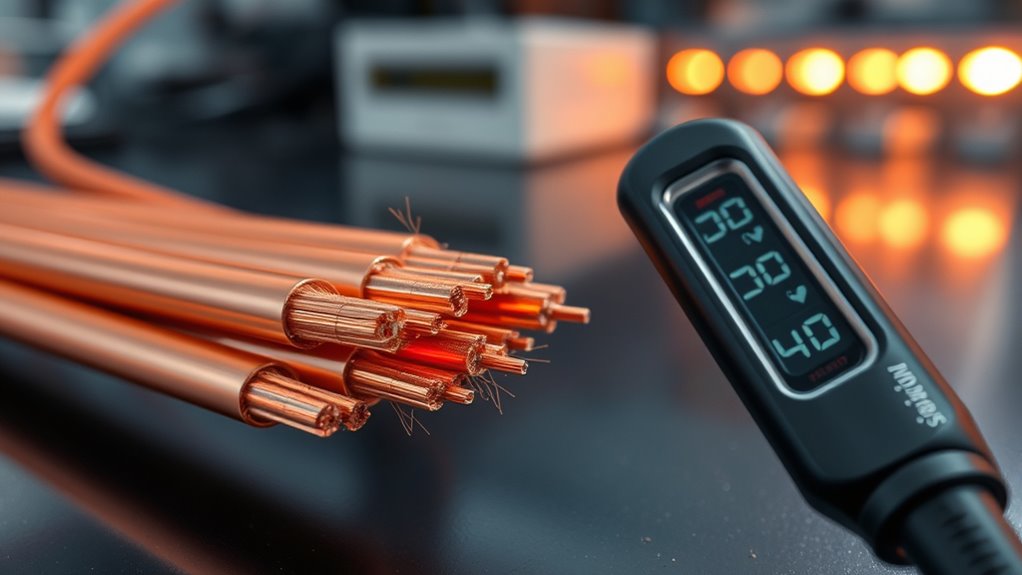

Effects of Temperature on Electrical Conductivity

Temperature substantially influences the electrical conductivity of cables, as increasing heat causes the atoms within the conductive material to vibrate more intensely. This heightened atomic vibration raises the electrical resistance, which directly affects how easily current flows through the cable. As temperature rises, the conductivity variation becomes evident: it generally decreases, making the material less efficient at conducting electricity. You’ll notice that at higher temperatures, the resistance increases, leading to potential power losses and overheating risks. This relationship is critical in designing and selecting cables for different environments. Understanding how temperature impacts electrical resistance helps you anticipate performance changes and implement measures to maintain ideal functionality, ensuring safety and efficiency in your electrical systems. Additionally, relationships between temperature and material properties can inform better insulation and cooling strategies to prolong cable lifespan, especially considering thermal expansion effects that may influence cable integrity over time. Proper management of temperature effects is essential for maintaining optimal cable performance and preventing failures. Recognizing the influence of material properties on conductivity can guide the development of more resilient cable designs tailored to specific temperature conditions.

Impact of Heat on Cable Insulation Materials

As heat interacts with cable insulation materials, it can considerably alter their properties and performance. Elevated temperatures accelerate UV degradation, weakening the polymer structure and reducing insulation lifespan. Heat also increases the risk of moisture ingress, which can lead to corrosion of conductors and compromise dielectric strength. When insulation absorbs moisture, its insulating properties diminish, causing potential electrical faults. Continuous exposure to high temperatures accelerates material breakdown, resulting in cracks or brittleness that make cables more vulnerable to damage. You should regularly inspect insulation for signs of UV damage or moisture buildup, especially in outdoor environments. Proper thermal management and protective coatings can help mitigate these effects, ensuring longer-lasting, reliable cable performance under varying heat conditions. Additionally, understanding signs of spoilage in insulation materials can aid in early detection of deterioration, which is crucial for maintaining cable safety and preventing failures. Implementing thermal insulation strategies can further extend the durability of cables exposed to heat.

Thermal Expansion and Mechanical Stress in Cables

When cables experience changes in ambient conditions, thermal expansion can induce significant mechanical stress. As temperatures rise, the materials in your cables expand, causing lengthening or deformation. Without proper allowances, this thermal expansion creates mechanical stress within the cables, which can lead to issues like deformation, cracking, or damage to insulation and conductors. Conversely, cooling causes contraction, potentially resulting in slack or tension that affects the cable’s integrity. Managing thermal expansion is essential to prevent these stresses from compromising performance. Proper design considerations, such as expansion joints or slack allowances, help accommodate temperature variations. Additionally, understanding the different properties of materials used in Kia Tuning components can aid in selecting appropriate materials that withstand temperature fluctuations. By understanding how thermal expansion influences mechanical stress, you can better ensure your cables maintain reliability and durability under fluctuating environmental conditions.

Temperature-Dependent Failure Modes in Cables

High temperatures can accelerate insulation degradation, increasing the risk of electrical failures. As the conductor expands, it may cause stress on the insulation and connections, leading to potential breakdowns. Understanding these failure modes helps you design more reliable cables for varying thermal conditions. Additionally, knowledge of resources and tools can assist in selecting appropriate materials and testing methods to ensure durability under temperature fluctuations. Employing thermal management techniques can further mitigate the adverse effects of heat on cable performance. Promoting a creative practice overview approach allows engineers to explore innovative solutions to thermal challenges, fostering resilience and adaptability in design. Incorporating material selection strategies based on temperature ratings can enhance the longevity and safety of cable systems.

Insulation Degradation Risks

Elevated temperatures accelerate the breakdown of cable insulation, increasing the risk of failure over time. Higher heat speeds up chemical reactions within the insulating material, weakening its structure and reducing insulation integrity. Additionally, increased temperatures can promote moisture ingress, which further compromises insulation by creating conductive paths that lead to short circuits or leaks. Moisture inside the cable accelerates deterioration, causing swelling, cracking, or delamination of the insulation layers. Over time, these effects diminish the cable’s ability to resist electrical stress, raising the likelihood of faults. Temperature fluctuations can also cause expansion and contraction cycles that stress the insulation material, further contributing to degradation. Managing temperature levels helps slow these degradation processes, ensuring the insulation remains effective and prolonging the cable’s service life. Proper installation techniques and material choices are essential for minimizing thermal stress on cables. Implementing thermal management strategies can significantly improve the longevity of cables by reducing thermal stress. Ignoring these risks can result in unexpected failures and costly repairs.

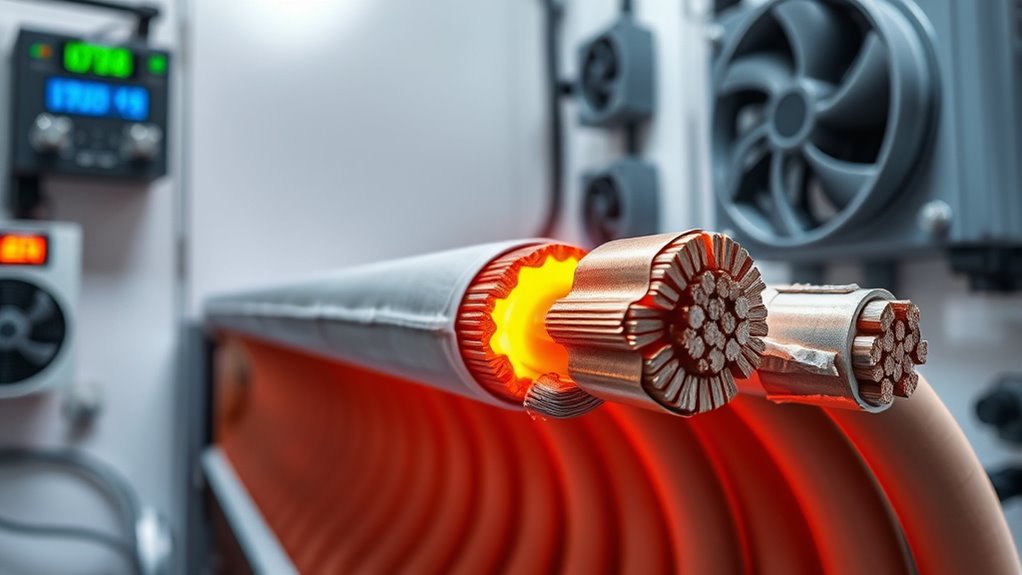

Conductor Expansion Effects

As the temperature rises, the conductor inside a cable expands, altering its physical dimensions. This process, known as thermal elongation, causes conductor expansion that can impact cable integrity. When the conductor elongates, it may create internal stresses, especially if the cable is confined or tightly bundled. These stresses can lead to fatigue over time, increasing the risk of cracks or fractures. Conductor expansion can also influence the contact pressure between the conductor and connectors, potentially causing loose connections or increased resistance. Additionally, repeated thermal elongation can weaken the conductor’s material, leading to premature failure. Monitoring and managing conductor expansion due to temperature changes is essential to maintain cable performance and prevent temperature-dependent failure modes. Proper design and installation help mitigate these risks effectively. Mechanical stresses resulting from expansion can accelerate wear and tear, further compromising cable longevity. Furthermore, understanding the temperature-dependent failure modes is crucial for developing more resilient cable systems. Implementing thermal management strategies can help control conductor expansion and reduce associated risks. Recognizing how material properties change with temperature can also aid in selecting suitable conductors for different environments.

Effects of Low Temperatures on Cable Flexibility and Brittleness

When temperatures drop, you’ll notice cables become more brittle and less flexible. This reduced flexibility makes handling and installation more difficult and increases the risk of damage. Understanding these effects helps you select and maintain cables suited for cold environments. Additionally, considering material properties can aid in choosing cables that maintain performance in low temperatures. Properly selecting cables that meet industry standards ensures safety and reliability during operation in cold conditions. Being aware of technological advancements can further enhance your ability to choose suitable cables for extreme environments.

Increased Cable Brittleness

Low temperatures cause cables to become more brittle, reducing their flexibility and making them more prone to cracking or breaking under stress. As the material ages in cold conditions, it loses its elasticity, increasing the risk of damage during installation or movement. This brittleness accelerates cable fatigue, especially when subjected to repeated bending or vibration, which can cause micro-cracks to form over time. The reduced ability to absorb mechanical stress means cables are more vulnerable to fractures and failures. When temperatures drop, the risk of sudden cable failure rises sharply because the brittle material cannot withstand normal operational stresses. To prevent issues, you need to contemplate the effects of low temperatures on cable durability and regularly inspect for signs of aging and fatigue.

Reduced Flexibility and Handling

Reduced flexibility and handling issues become more pronounced in low-temperature conditions, making cables harder to manipulate and install. When temperatures drop, cables experience temperature-induced stiffness, which markedly reduces their bendability. This stiffness increases handling challenges, as you’ll find it difficult to shape or position the cables as needed. The increased brittleness from cold environments compounds these issues, risking cracks or damage during installation. As a result, working with cold cables demands extra caution and effort, often requiring heating or special tools to improve flexibility. Without addressing these challenges, installation becomes more time-consuming and prone to damage, ultimately impacting the overall performance and longevity of the cable system. Proper preparation and understanding of temperature effects are essential for smooth handling in cold conditions.

Thermal Management Strategies for Cable Systems

Effective thermal management is essential for maintaining ideal performance and longevity of cable systems, especially as ambient temperatures fluctuate. You should implement strategies like proper cable color coding to easily identify cables operating at different temperature tolerances, reducing installation errors and enhancing safety. Using cooling techniques such as ventilation, heat sinks, or insulation helps prevent overheating, which can compromise insulation integrity and cause failures. Regular monitoring of temperature levels ensures your system stays within safe limits, safeguarding installation safety. Proper routing and spacing of cables also promote airflow and dissipate heat effectively. By adopting these thermal management strategies, you minimize risks of thermal degradation, improve reliability, and extend the lifespan of your cable systems.

Material Selection for Temperature-Resilient Cables

Selecting the right materials is vital when designing cables that can withstand high or fluctuating temperatures. You should consider materials like conductive polymers, which offer excellent electrical properties and thermal stability. Conductive polymers are lightweight, flexible, and resistant to heat, making them suitable for harsh environments. Thermoplastic elastomers also play a fundamental role because they combine the flexibility of rubber with the processability of plastics, providing durability at elevated temperatures. These materials help maintain cable integrity and performance under thermal stress. When choosing materials, prioritize those with high melting points, chemical resistance, and electrical insulation qualities. Proper selection ensures your cables remain reliable, flexible, and efficient, even in demanding temperature conditions.

Monitoring and Testing Cables Under Varying Temperature Conditions

After choosing materials capable of withstanding temperature fluctuations, it’s important to regularly monitor and test cables to guarantee they perform reliably under varying thermal conditions. You should focus on key aspects like fiber optic integrity and cable shielding effectiveness. Here are three essential steps:

- Conduct thermal cycling tests to observe fiber optic signal stability and identify potential performance drops.

- Measure cable shielding effectiveness under different temperatures to prevent electromagnetic interference.

- Use specialized equipment to detect insulation degradation or microcracks caused by thermal stress.

Regular testing ensures that cables maintain their performance and safety standards. Monitoring allows you to identify issues early, preventing failures and costly repairs. This proactive approach guarantees reliable operation, especially in environments with fluctuating temperatures.

Frequently Asked Questions

How Does Temperature Influence Cable Lifespan Over Time?

Higher temperatures accelerate thermal aging in cable insulation, which shortens its lifespan over time. When you expose cables to elevated heat, the insulation’s material deteriorates faster, leading to increased risk of failure. To guarantee longevity, you should keep cables within recommended temperature ranges, allowing the insulation to resist thermal aging. Proper cooling and insulation selection are key to maintaining cable performance and extending its service life.

Are There Specific Environmental Conditions That Exacerbate Temperature Effects?

Environmental humidity and mechanical stress can worsen temperature effects on cables. High humidity causes corrosion and insulation degradation, accelerating wear. Mechanical stress, like bending or pulling, strains the cable’s structure, making it more vulnerable to heat damage. When these conditions combine with elevated temperatures, they markedly reduce your cable’s lifespan and performance. To prevent this, guarantee proper insulation, minimize mechanical stress, and control environmental humidity levels around your cables.

What Are the Cost Implications of Temperature-Resistant Cable Materials?

Temperature-resistant cable materials typically have higher material costs, which can increase your overall project expenses. You might also face higher installation costs since these cables often require specialized handling or additional protective measures. While the upfront investment is greater, these materials help prevent failures and reduce maintenance costs over time, ultimately saving you money by ensuring reliable performance in extreme temperatures.

Can Thermal Cycling Cause Long-Term Damage to Cables?

Yes, thermal cycling can cause long-term damage to cables. As you experience repeated temperature fluctuations, thermal fatigue occurs, leading to material degradation over time. This process weakens the cable’s insulation and conductive components, increasing the risk of failures. You should regularly inspect cables subjected to thermal cycling and consider using materials designed to withstand thermal fatigue, ensuring longevity and reliable performance in fluctuating temperatures.

How Do Temperature Variations Affect Underground Versus Overhead Cables?

Imagine your cables as dancers responding to the music of temperature changes. Overhead cables face more thermal expansion and insulation degradation from sun and wind, risking sagging or damage. Underground cables are shielded but can still suffer from insulation degradation due to shifting soil temperatures. Both types need proper insulation to withstand temperature variations, ensuring they perform reliably without long-term damage from constant thermal expansion and contraction.

Conclusion

Understanding how temperature affects cable performance is like steering a delicate balance on a tightrope. By selecting the right materials, implementing effective thermal management, and regularly monitoring conditions, you can keep your cable systems resilient against temperature swings. Like a skilled conductor guiding an orchestra, managing these factors ensures smooth operation and longevity. Stay proactive, and you’ll prevent failure modes from striking a sour note, maintaining harmony in your electrical infrastructure.