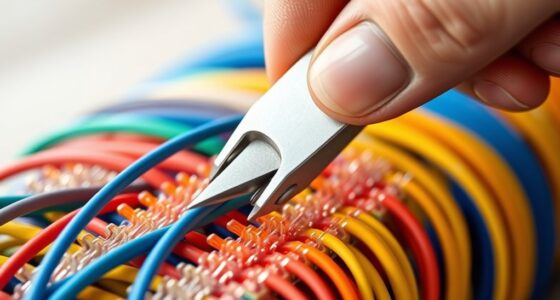

Many people overlook how critical the right tools are when splicing fiber optic cables. Without proper equipment, achieving a clean, precise connection can be nearly impossible, leading to signal loss or failure. While you may think any tool will do, specialized fiber optic splicing tools are designed to guarantee maximum performance and durability. Understanding which tools matter most can make a significant difference in your installations—so, let’s explore what sets them apart.

Key Takeaways

- Essential tools include fusion splicers, mechanical splice connectors, fiber cleavers, stripping tools, and cleaning supplies.

- Proper tool selection ensures precise alignment, clean preparation, and optimal splice quality.

- Fusion splicers provide low-loss, high-strength connections through electric arc welding.

- Mechanical splicing offers quick repairs with a precision alignment sleeve for reliable joins.

- Environmental protection tools like protective sleeves extend splice lifespan and maintain network performance.

Fiber optic splicing tools are essential for ensuring reliable and efficient connections in fiber optic networks. They enable you to join fibers with precision, minimizing signal loss and maintaining high data transfer rates. Whether you’re working on a large installation or a small repair, understanding the different connector types and splicing techniques is crucial to achieving optimal results. Connector types vary widely, including FC, SC, ST, LC, and MTP/MPO connectors, each designed for specific applications and environments. Choosing the right connector type depends on your network’s requirements, such as speed, space constraints, and compatibility. Properly selecting and installing connectors ensures a secure fit and reduces the risk of connection failure, which can cause network disruptions or data loss.

When it comes to splicing techniques, two primary methods dominate: fusion splicing and mechanical splicing. Fusion splicing involves permanently joining two fibers by melting their ends together using an electric arc. This technique offers the lowest loss and highest strength, making it ideal for long-distance or high-bandwidth applications. To perform fusion splicing, you’ll need a fusion splicer—an advanced tool that carefully aligns and fuses fibers with minimal loss. Mechanical splicing, on the other hand, joins fibers temporarily using a precision connector or alignment sleeve. It’s quicker and more suitable for field repairs or situations where temporary connections suffice. Mechanical splices are easier to perform but usually introduce slightly higher loss compared to fusion splicing.

Choosing the right splicing technique depends on your project’s specific needs. Fusion splicing offers durability and the best performance but requires precise equipment and preparation. Mechanical splicing is faster and more flexible, making it a good choice for quick fixes or testing scenarios. Regardless of your method, proper preparation is key. You’ll need to carefully strip the fiber coating, clean the fibers thoroughly, and cleave the fibers with a high-quality cleaver to ensure smooth, flat ends. After splicing, you’ll often use connector adapters or protective sleeves to safeguard the splice point from environmental damage. Additionally, using the appropriate vetted tools can significantly improve splice quality and reduce the risk of errors.

Frequently Asked Questions

What Safety Precautions Are Necessary During Fiber Splicing?

During fiber splicing, you need to prioritize safety by always wearing protective eyewear to shield your eyes from laser light and glass shards. Handle fibers carefully, using proper handling techniques to prevent injury and damage to the fibers. Keep your workspace clean and well-lit, and avoid rushing. Follow manufacturer instructions and safety guidelines to guarantee a safe splicing process, reducing the risk of accidents or exposure to harmful materials.

How Do Environmental Conditions Affect Splicing Tool Performance?

Environmental conditions can dramatically influence your splicing tool performance. When temperature sensitivity strikes, tools may malfunction or become less precise, risking fiber damage. Moisture impact can cause corrosion or slipping, complicating the process. You need to stay vigilant—extreme heat, cold, or humidity can jeopardize your splice quality. Keep your workspace controlled, and always check environmental conditions before starting. Neglecting these factors could mean costly errors and compromised connections.

Can Splicing Tools Be Used for Different Fiber Types?

Yes, splicing tools can be used for different fiber types, thanks to their versatility and compatibility features. You should choose tools designed for various fiber types like single-mode and multi-mode fibers, ensuring proper fiber compatibility. Tool versatility allows you to work efficiently across different projects without switching equipment. Always verify the specifications to match your fiber type, which helps achieve precise splices and maintains ideal performance.

What Is the Average Lifespan of Fiber Splicing Tools?

You might wonder how long your fiber splicing tools will last. The lifespan estimation varies, but with proper tool maintenance, you can extend their life markedly. On average, quality splicing tools last between 3 to 5 years, depending on usage and care. Neglecting maintenance could shorten that, risking costly replacements. Stay vigilant, keep them clean and calibrated, and you’ll enjoy reliable performance and a longer lifespan, ensuring your splicing projects stay on track.

Are There Portable Splicing Tools Suitable for Fieldwork?

Yes, there are portable tools designed specifically for field splicing, making your job easier on-site. These portable tools are lightweight, durable, and easy to handle, enabling you to perform precise splicing in various field conditions. They often include features like integrated cleavers, stripping tools, and compact fiber holders. With these field splicing tools, you can achieve efficient, high-quality splices without needing bulky equipment or a dedicated lab space.

Conclusion

By choosing the right fiber optic splicing tools, you’re crafting the backbone of a resilient network. Think of these tools as your trusted brush and chisel, shaping a masterpiece of seamless connections. When you prioritize quality and precision, your splices become the sturdy bridges that carry light’s whisper across distances. Remember, a well-made splice isn’t just a connection—it’s the heartbeat of a reliable, enduring network, pulsing with clarity and strength.