Imagine a cable’s specifications as its secret language, revealing what it can truly handle under different conditions. Understanding these details helps you choose the right cable for your project and avoid potential hazards. But knowing where to find and interpret this information can be tricky. So, to guarantee safety and performance, it’s important to learn how to decode these ratings accurately—you’ll be surprised what you can uncover.

Key Takeaways

- Identify the voltage rating, current capacity, and temperature limits printed on the cable or in datasheets.

- Understand insulation type and material to determine environmental suitability and resistance properties.

- Check conductor material (copper or aluminum) to assess conductivity, flexibility, and application compatibility.

- Match the cable’s ratings with your project’s electrical load, environmental conditions, and safety requirements.

- Consult manufacturer datasheets or markings for detailed specifications to ensure proper and safe cable selection.

Understanding cable specifications and ratings is vital for selecting the right cable for your electrical projects. When you’re evaluating cables, one of the first things to consider is the insulation types. The insulation material determines how well the cable resists heat, moisture, chemicals, and electrical interference, which directly impacts safety and performance. Common insulation types include PVC, rubber, XLPE, and Teflon, each suited for different environments and applications. PVC is popular for general use because it’s affordable and flexible, but it may not withstand high temperatures. XLPE offers better heat resistance, making it suitable for more demanding settings. Rubber insulation provides excellent flexibility and durability, ideal for portable or movable installations. Understanding these insulation types helps you match the cable to your project’s environmental conditions, guaranteeing longevity and safety. Recognizing the importance of insulation properties helps ensure you select a cable that performs reliably under your specific conditions.

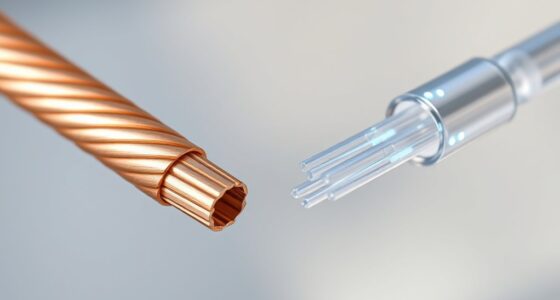

Alongside insulation, conductor materials play a vital role in a cable’s performance. Conductors are the core components that carry current, and their material impacts conductivity, flexibility, and durability. Copper is the most common conductor material because of its high electrical conductivity, flexibility, and resistance to corrosion. It’s ideal for most residential and commercial applications. Aluminum conductors are lighter and less expensive, making them suitable for long-distance power transmission, but they are less flexible and more prone to expansion and contraction with temperature changes. Some specialized cables may incorporate other materials, but copper and aluminum dominate the market. When reading cable ratings, you’ll often see references to the conductor material, which indicates how well the cable can handle current loads and how durable it will be over time.

In addition to insulation types and conductor materials, ratings such as voltage capacity, current-carrying capacity, and temperature limits give you a complete view of a cable’s capabilities. These ratings are usually printed directly on the cable or included in technical datasheets. By paying close attention to these specifications, you guarantee that the cable you choose can safely handle the electrical load, environmental conditions, and physical stresses involved in your project. Combining knowledge about insulation types and conductor materials with the ratings provided enables you to make informed decisions, reducing the risk of failures, hazards, and costly replacements down the line. Ultimately, understanding these fundamental aspects empowers you to select cables that are both safe and efficient for your specific electrical needs.

Frequently Asked Questions

How Do Environmental Conditions Affect Cable Ratings?

Environmental conditions directly impact cable ratings by affecting temperature effects and moisture influence. High temperatures can cause cables to overheat, reducing their current-carrying capacity and risking damage. Moisture can lead to corrosion and insulation breakdown, compromising safety and performance. You should always consider these factors when selecting cables, guaranteeing they meet environmental demands to maintain reliability and prevent failures. Properly rated cables withstand environmental stresses and ensure safe operation.

What Are the Differences Between Different Cable Insulation Types?

Did you know there are over 50 types of wire insulation? Different cable insulation types, like PVC, XLPE, or rubber, vary in flexibility, heat resistance, and durability. Cable jackets safeguard the wire insulation and influence flexibility and environmental resistance. Your choice depends on your application’s needs—PVC offers affordability, while XLPE handles higher temperatures. Understanding these differences guarantees you select the right cable for safety and longevity.

How Do I Interpret Cable Flexibility Ratings?

You interpret cable flexibility ratings by looking at flexibility testing results, which show how well a cable withstands repeated bending without damage. Pay attention to the cable bend radius specified, as it indicates the minimum bend radius you should maintain to avoid stressing the cable. A lower bend radius rating means higher flexibility, making the cable suitable for tight spaces or dynamic applications. Always follow these ratings to guarantee peak performance and longevity.

What Certifications Should I Look for on Cable Labels?

You should look for certifications like UL, CSA, or IEC on cable labels—these signals guarantee safety and quality. Pay close attention to certification standards, as they guarantee the cable meets strict industry requirements. Labels often hide these vital details, so check carefully. Ignoring these certifications can risk safety and performance. Always prioritize cables with recognized standards to protect your project and ensure reliable, compliant operation.

How Do Aging and Wear Impact Cable Performance Ratings?

Aging and wear can greatly affect your cable’s performance ratings by decreasing jacket durability and increasing conductor fatigue. Over time, the jacket may crack or become brittle, compromising insulation, while repeated bending stresses weaken the conductor, leading to potential failures. These factors diminish the cable’s capacity to handle rated loads safely, so regularly inspecting and replacing worn cables guarantees ideal performance and safety in your electrical systems.

Conclusion

Don’t let confusing markings or unfamiliar codes hold you back. By understanding how to read cable specifications and ratings, you guarantee your installation is safe, reliable, and long-lasting. Even if it seems complicated at first, taking the time to learn these details pays off in performance and safety. Remember, properly rated cables prevent failures and protect your equipment—so always verify their specifications before you connect. Your system’s safety depends on it.