Understanding cable ratings helps you choose the right wiring for safety and compliance. Plenum cables are designed for air handling spaces with fire-resistant, low-smoke materials, making them ideal for ceilings and above floors. Riser cables suit vertical runs between floors with fire-resistant insulation. CM cables are general-purpose, used indoors with standard insulation. Knowing these differences guarantees you meet safety standards. Keep exploring to learn how each type fits your project needs and regulations.

Key Takeaways

- Plenum cables are designed for air handling spaces and have fire-resistant, low-smoke materials, making them more suitable for high-risk areas.

- Riser cables are intended for vertical runs between floors, offering fire-resistant properties but generally less expensive than plenum cables.

- CM (Communications) cables are for general indoor use, providing basic fire safety and lower costs, suitable for non-critical environments.

- Certification standards (UL/IEEE) ensure each cable type meets specific fire safety and performance requirements for its rated environment.

- Choosing the correct cable rating depends on installation location, fire safety regulations, and environmental safety considerations.

What Is a Plenum Cable and Its Characteristics

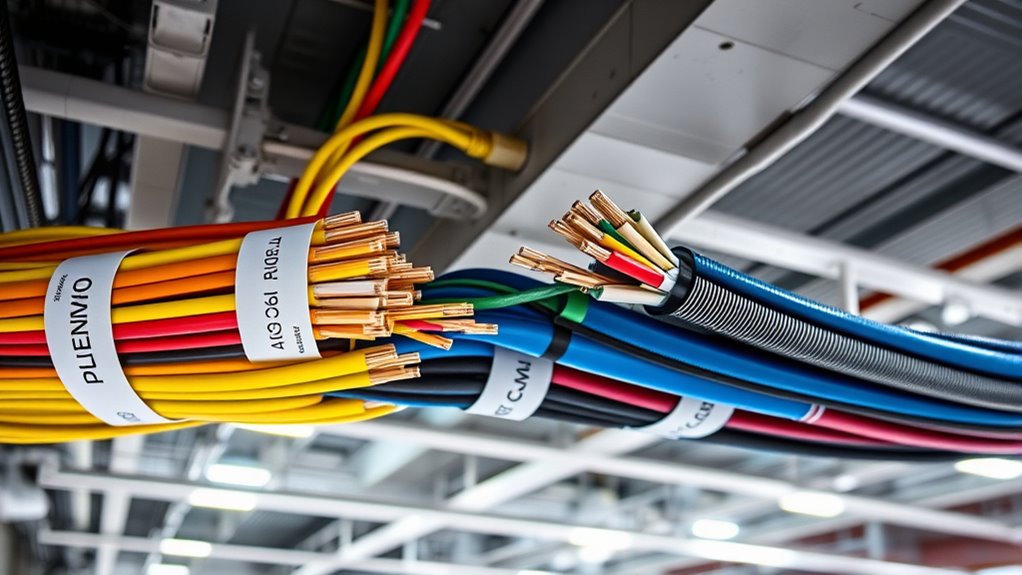

What exactly is a plenum cable, and why is it important? A plenum cable is designed for use in the air handling spaces of buildings, like above ceilings and below floors. Its core features include a special fire-resistant coating that minimizes smoke and toxic fumes if it catches fire, making it safer for building occupants. Unlike standard electrical wiring, plenum cables often incorporate advanced materials suitable for fiber optics or traditional electrical wiring, ensuring reliable data transmission and power delivery. Their construction prevents the spread of flames, which is vital in maintaining fire safety codes. If you’re installing cabling in areas with air circulation, choosing a plenum-rated cable helps you stay compliant and enhances overall safety. Additionally, fire safety regulations require the use of such cables in specific building zones to prevent the rapid spread of fire and smoke. Using properly rated cables can also help avoid costly code violations and potential safety hazards. Moreover, understanding the material composition of these cables is essential for ensuring they meet safety standards and perform as expected in critical environments. Furthermore, the material properties of plenum cables contribute to their ability to withstand high temperatures and reduce toxic emissions during a fire.

Understanding Riser Cables and Their Usage

Riser cables are designed with specific materials to meet fire safety standards and prevent the spread of flames between floors. You’ll find they’re typically used in vertical runs within walls and between levels of a building. Understanding their composition and proper installation environments helps make sure of compliance and safety. Additionally, knowledge of cultural impact and the influence of technology on artistic expression can inform the development of safer, more innovative cable products. Recognizing the importance of fire safety regulations ensures that riser cables are properly selected and installed to meet local building codes and standards.

Riser Cable Materials and Composition

To guarantee safety and fire resistance, riser cables are constructed with specialized materials that limit the spread of flames and reduce smoke production. These cables often include fiber optic or copper conductors, which are encased in durable, fire-resistant electrical insulation. The insulation materials are designed to withstand high temperatures and prevent the ignition of surrounding materials in case of fire. Riser cables typically feature a core made from flame-retardant compounds that slow flame propagation. The outer jackets are made from materials like PVC or low-smoke zero-halogen (LSZH) compounds, which emit minimal smoke and toxic fumes. This composition assures that riser cables maintain structural integrity and safety, making them suitable for vertical runs between floors while complying with fire safety standards. Additionally, fire safety standards ensure that these cables meet strict criteria for fire resistance and smoke emission, further enhancing building safety.

Fire Safety Regulations

Understanding fire safety regulations is essential when selecting cables for building installations, as these rules guarantee both safety and compliance. Riser cables must meet specific standards to prevent fire spread between floors. Cable durability plays a crucial role, ensuring the insulation materials resist heat and flame in case of fire. Regulations specify the use of fire-resistant insulation materials that minimize toxic smoke and prevent electrical failure during emergencies. These standards also require cables to maintain their integrity under high temperatures, reducing the risk of electrical faults. By choosing cables that adhere to fire safety regulations, you ensure that the infrastructure remains safe during a fire event. Properly rated riser cables protect occupants and property, aligning safety with building codes and industry best practices.

Typical Installation Environments

Choosing the right cables for building installations depends heavily on the environment where they’ll be installed. Riser cables are designed for vertical runs between floors, making them suitable for stairwells and elevator shafts. They typically use fire-resistant cable material and specific installation techniques to prevent fire spread. Understanding the typical environments helps you select the appropriate cable rating. Here’s a quick guide:

| Environment | Cable Material | Installation Techniques |

|---|---|---|

| Vertical shafts | Fire-resistant, low-smoke | Secure with proper supports |

| Between floors | Riser-rated, flame-retardant | Keep away from moisture |

| Elevator shafts | Non-corrosive, durable | Follow fire safety protocols |

| Stairwells | Low-smoke, fire-resistant | Use protective conduit |

| Mechanical chases | Flame-retardant, flexible | Maintain proper separation |

Additionally, selecting cables with proper insulation is essential to ensure safety and compliance with building codes. Using cable ratings that meet industry standards helps prevent hazards like fire propagation and ensure long-term performance. Proper installation techniques are also critical to maintain safety and compliance throughout the building’s lifespan. Moreover, understanding the importance of fire safety standards ensures that cables are capable of preventing or delaying the spread of fire in critical areas.

Features of CM (Communications) Cables

Communications (CM) cables are designed to support data transmission in various building environments, offering features that guarantee reliable performance and safety. Their cable insulation is crafted to protect signal integrity and prevent interference, ensuring clear and consistent data flow. CM cables often incorporate fire-resistant materials, which slow down or prevent the spread of flames if a fire occurs, enhancing safety in commercial and residential settings. These cables are built to withstand everyday wear and environmental factors, making them suitable for indoor use. Additionally, their insulation and fire-resistant features contribute to compliance with safety standards. Overall, CM cables combine durability with safety features, ensuring your data connections remain stable while minimizing fire risks. They are frequently tested to meet industry standards for fire safety and environmental resilience, providing added peace of mind for installation in critical areas.

Comparing Safety Standards for Different Cable Ratings

Safety standards for different cable ratings guarantee that your wiring meets specific fire, environmental, and performance requirements. These standards dictate how cable insulation is designed to resist heat, flame, and environmental hazards. For plenum cables, safety standards emphasize low smoke production and non-toxic fumes due to their use in air-handling spaces. Riser cables, meanwhile, must prevent fire spread between floors, requiring specialized cable insulation that withstands vertical riser conditions. CM (Communications) cables have less stringent safety standards, focusing on signal integrity rather than fire safety. Understanding these differences helps you select the right cable rating for your environment, ensuring compliance with safety standards and reducing fire risks. Each rating’s safety standards reflect its intended use, making them vital for a safe, code-compliant installation. Considering environmental considerations ensures that your installation minimizes impact on the natural surroundings and promotes sustainable practices. Additionally, adhering to industry standards is crucial for maintaining overall safety and performance in electrical wiring. Recognizing the different safety standards for each cable type can also help prevent potential code violations and safety hazards. Moreover, understanding the specific fire safety requirements associated with each cable rating ensures that your installation remains compliant with local building codes and reduces the risk of fire-related incidents.

Installation Guidelines for Plenum, Riser, and CM Cables

Proper installation of plenum, riser, and CM cables is essential to guarantee safety, compliance, and peak performance. To achieve this, you must follow specific cable installation techniques that prevent damage and ensure proper function. Use appropriate cable routing strategies, such as securing cables neatly and avoiding sharp bends or excessive tension. Keep cables separated from sources of heat, moisture, and electrical interference. For plenum spaces, ensure cables are rated for air-handling environments, and use approved supports and fasteners. Riser cables require proper spacing to prevent fire spread, while CM cables should be installed away from potential physical damage. Always adhere to local codes and manufacturer guidelines to maintain safety and ascertain your installation remains compliant and reliable. Additionally, selecting the correct cable concentration and application is crucial for optimal performance and safety. Understanding cable ratings helps ensure that the right type of cable is used in the appropriate environment, thereby reducing risks and enhancing safety. Proper cable installation techniques not only improve safety but also extend the lifespan of your cabling infrastructure. Being familiar with state-specific benefits can further optimize your planning and compliance efforts.

Material Composition and Fire-Resistance Properties

Understanding the material composition of plenum, riser, and CM cables is essential because it directly affects their fire-resistance properties. The cable material determines how well a cable can withstand heat and resist fire spread. Plenum cables typically use fire-retardant, low-smoke materials like fluorinated ethylene propylene (FEP), which provide high fire resistance properties suitable for air-handling spaces. Riser cables often feature fire-retardant jackets made from materials such as PVC or riser-rated compounds, offering moderate fire resistance. CM cables usually use standard PVC insulation, which has lower fire resistance properties and is suitable for general-use environments. Knowing the differences in cable material composition helps ensure you select the right cable for safety and compliance in your specific application. Additionally, selecting fire-resistant materials for cables can significantly improve safety and reduce the risk of fire hazards. Understanding material composition is crucial for ensuring compliance with building codes and safety standards, especially when considering the fire-resistance properties of various cable types.

When to Choose Each Type of Cable for Your Project

Choosing the right type of cable depends on your specific project requirements and the environment where the cables will be installed. If you need cables with superior fire resistance and non-flammable cable insulation, a plenum-rated cable is ideal for air-handling spaces, ensuring safety and compliance. Riser cables are suitable for vertical runs between floors, offering fire-resistant insulation but not designed for air plenums. For general indoor applications where fire resistance isn’t a primary concern, CM-rated cables work well, providing basic protection. Consider the risks of fire spread, the installation environment, and building codes to determine which cable rating fits best. Selecting the proper cable ensures safety, regulatory compliance, and excellent performance tailored to your project’s environment.

Cost Implications of Different Cable Ratings

The cost of cable ratings can considerably impact your project’s budget, and these expenses vary depending on the type of cable you select. Plenum cables tend to be more expensive than riser or CM cables because of their special fire-resistant materials. When doing a cost comparison, keep in mind that choosing the right cable rating involves balancing upfront costs with long-term safety and compliance. Riser cables are typically less costly than plenum but still offer good fire resistance, making them suitable for vertical runs. CM cables are generally the most affordable but lack the fire-resistant properties required in certain environments. Your budget considerations should include not only the initial purchase price but also installation, safety, and potential code compliance costs.

Regulatory Compliance and Code Requirements

You need to guarantee your cables meet building code compliance and fire safety standards to keep your project safe and legal. Industry certification regulations also dictate which cable types are acceptable for specific applications. Ignoring these requirements can lead to costly penalties or safety hazards down the line.

Building Code Compliance

Are you aware of how crucial building codes are in ensuring cable safety and performance? Building codes set the standards for cable installations, ensuring they meet safety, durability, and environmental requirements. When selecting cable types like plenum, riser, or CM, compliance with local regulations is essential. Fiber optics and wireless alternatives are also affected by these standards, often influencing infrastructure choices. Codes specify the appropriate cable ratings for different environments, preventing hazards like fires or electrical failures. They also mandate proper installation practices to maintain safety and performance. Staying up-to-date with these codes helps avoid legal issues and ensures your building’s systems operate reliably. Ultimately, adhering to building code compliance protects occupants and guarantees your cabling system performs as intended.

Fire Safety Standards

Building codes not only define proper cable installation practices but also establish fire safety standards that protect occupants and property. These standards specify requirements for cable insulation and fire retardant properties to minimize fire hazards. For example, plenum-rated cables must have fire retardant insulation that prevents the spread of flames and toxic fumes in air-handling spaces. Riser cables also require fire-resistant features, ensuring they don’t propagate fire between floors. Compliance with these fire safety standards is essential to meet regulatory requirements and avoid penalties. By choosing cables with appropriate fire retardant and insulation properties, you help reduce fire risks, safeguard lives, and protect property. Always verify that cable ratings align with local fire safety codes to ensure safety and legal compliance.

Industry Certification Regulations

How do industry certification regulations guarantee that cables meet safety and performance standards? They require rigorous testing and adherence to standards set by organizations like UL and IEEE. These certifications ensure fiber optics and power conductors can withstand environmental and electrical stresses. Certification marks on cables indicate compliance, giving you confidence in their safety and durability. Visualize the standards as a matrix of requirements:

| Certification Type | Focus Area |

|---|---|

| Plenum | Fire safety, low smoke |

| Riser | Vertical installation |

| CM | General use in walls |

| UL/IEEE | Electrical performance |

This framework ensures your cables are safe, reliable, and fit for their specific applications.

Frequently Asked Questions

How Do I Determine the Right Cable Rating for My Building?

To determine the right cable rating for your building, consider fire safety and adhere to installation guidelines. Check local building codes and regulations to identify whether plenum, riser, or communication cables are required. Evaluate your environment, such as whether cables are in air handling spaces, which need plenum-rated cables for safety. Always consult with a professional to guarantee proper selection, compliance, and maximum fire safety standards.

Are Plenum Cables More Expensive Than Riser or CM Cables?

Yes, plenum cables are generally more expensive than riser or CM cables. Their higher cost is due to special fire-resistant materials that meet strict safety standards. When considering the cost comparison, keep in mind that installation costs may also be higher because plenum cables require careful handling and specific installation practices. However, investing in plenum cables can be essential for safety in certain building areas, potentially saving costs in emergencies.

Can I Mix Different Cable Ratings in the Same Installation?

You can mix different cable ratings in the same installation, but you must follow fire safety and installation regulations. Make certain that cables with higher fire safety ratings, like plenum-rated cables, are used in areas requiring strict fire safety standards, while riser or CM cables are suitable elsewhere. Always consult local codes and standards to prevent fire hazards and ensure compliance, protecting both the building and its occupants.

What Are the Long-Term Durability Differences Among These Cables?

You’ll find plenum cables generally more durable long-term because of their fire-resistant materials, designed to withstand higher temperatures and slow fire spread. Riser cables, while also fire-resistant, may not last as long under extreme conditions due to different material compositions. CM cables, primarily made for general use, tend to have lower fire resistance, making them less durable over time in demanding environments. Choose wisely for safety and longevity.

How Do Climate Conditions Affect Cable Selection and Performance?

Climate impact and environmental considerations play a vital role in your cable selection and performance. In harsh climates, you need cables with better insulation and weather resistance to prevent degradation. Moisture, extreme temperatures, and UV exposure can weaken cables over time, so choose ratings suited for your environment. Properly evaluating climate conditions guarantees reliable performance, reduces maintenance needs, and extends cable lifespan, ultimately safeguarding your infrastructure against environmental stressors.

Conclusion

Choosing the right cable rating is like selecting the perfect thread to weave a safe, sturdy fabric for your project. By understanding the differences between plenum, riser, and CM cables, you guarantee your installation is both safe and compliant. Remember, the right cable isn’t just a choice—it’s the backbone that keeps your building’s safety net intact, preventing sparks from turning into unforeseen flames. Make informed decisions to keep your environment secure and compliant.