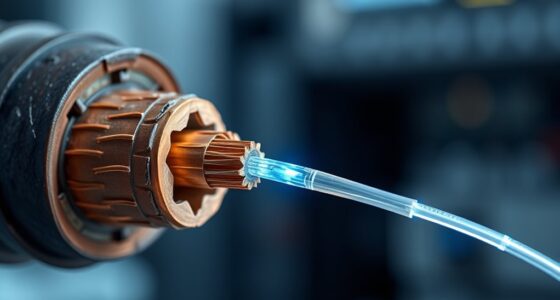

Bend-insensitive fiber cables are designed to handle tighter bends without losing signal quality, making them a practical choice for complex or space-constrained installations. Their specialized coatings help prevent microbending and macrobending losses, ensuring stable performance even when routed around obstacles. But to get the most out of these cables, proper handling during installation is essential. Understanding their features and best practices can substantially impact your network’s reliability and longevity.

Key Takeaways

- Bend-insensitive fiber cables allow tighter bends without signal loss, simplifying installation in confined or challenging spaces.

- They require compatible connectors, such as LC, SC, or MPO, designed to minimize insertion loss and maintain performance.

- Proper handling, including maintaining recommended bend radii and gentle routing, extends fiber lifespan and preserves signal quality.

- Using appropriate tools and techniques during installation reduces microbending and macro-bending losses.

- Regular monitoring and correct slack management ensure long-term network reliability and optimal fiber performance.

Bend-insensitive fiber cables are revolutionizing the way we deploy optical networks by allowing for tighter bends without compromising performance. This advancement means you can install fiber in more challenging spaces without worrying about signal loss or damage. When working with these cables, understanding fiber optic connectors and proper installation techniques becomes essential to maximize their benefits and guarantee a reliable, high-quality connection.

You’ll find that bend-insensitive fibers are more forgiving when it comes to routing around obstacles, corners, or confined areas. They are designed with special coatings and materials that reduce microbending and macrobending losses. But to truly leverage these advantages, you need to pay attention to fiber optic connectors. Choosing the right connectors—such as LC, SC, or MPO—affects signal integrity and ease of installation. These connectors are designed to minimize insertion loss and secure a stable, reliable connection, even in tight bends. When connecting bend-insensitive fiber, always handle the connectors carefully to avoid stressing the fiber, which can introduce microbends and degrade performance over time.

Your installation techniques play a critical role in maintaining the integrity of bend-insensitive fiber cables. Proper bend radius is paramount; even though these cables tolerate tighter bends, exceeding the recommended radius can still cause damage or performance issues. Always check manufacturer specifications and adhere to the recommended bend radius during installation. When routing the fiber through conduits or around obstacles, use gentle curves rather than sharp bends. Employ appropriate slack management practices—such as using fiber organizers or bend-radius guides—to prevent accidental kinks or excessive stress on the cable.

Another key aspect of installation is avoiding excessive pulling force during cable deployment. Use proper tools and techniques to prevent microcracks or fractures that could impair the fiber’s performance. When terminating fiber optic connectors, follow manufacturer guidelines meticulously to guarantee clean, precise connections. Proper cleaning and polishing of connectors before installation can prevent signal degradation and minimize insertion loss. Additionally, understanding fiber bend radius and adhering to best practices can significantly prolong the lifespan of your fiber network.

In addition, document your installation process thoroughly, noting bend radii and connector types used, so future maintenance or troubleshooting can be addressed efficiently. Training personnel on correct handling and installation techniques will further reduce the risk of damaging the fiber or connectors. By combining the right fiber optic connectors with careful, well-informed installation techniques, you can unlock the full potential of bend-insensitive fiber cables, ensuring high performance and longevity for your optical network.

Frequently Asked Questions

How Do Bend-Insensitive Fibers Compare in Cost to Traditional Fibers?

Bend-insensitive fibers typically cost more upfront than traditional fibers, but their durability and flexibility can reduce installation and maintenance costs over time. When you do a cost comparison, you’ll find that their higher price is often offset by fewer repairs and easier installation in tight spaces. An affordability analysis shows that, despite the initial expense, bend-insensitive fibers offer better long-term value, especially in complex or challenging environments.

What Are the Best Practices for Installing Bend-Insensitive Fiber Cables?

When installing bend-insensitive fiber cables, follow strict installation guidelines to prevent damage. Keep the bending radius within the manufacturer’s recommended limits, usually larger than traditional fibers, to maintain signal integrity. Avoid sharp bends and pinching, and use appropriate cable management techniques like cable trays and gentle curves. Carefully plan your routing paths, and always handle the cables gently to guarantee ideal performance and longevity.

Are Bend-Insensitive Fibers Compatible With Existing Network Equipment?

Think of bend-insensitive fiber cables as a universal translator for your network. They’re highly compatible with existing equipment, ensuring smooth network integration without needing major upgrades. You won’t face compatibility issues, so your current network gear can connect seamlessly. This means you can enhance your infrastructure confidently, knowing these fibers work well with your current setup, making your network more resilient and adaptable without the hassle of extensive rewiring or replacements.

How Do Bend-Insensitive Fibers Perform in Extreme Environmental Conditions?

Bend-insensitive fibers perform well in extreme environmental conditions thanks to their enhanced environmental durability, resisting temperature fluctuations, moisture, and mechanical stress. This makes them ideal for challenging installations, reducing challenges like fiber breakage or signal loss. You’ll find that their durability minimizes installation challenges, ensuring reliable performance even in harsh environments. Overall, they provide a robust solution that maintains high signal quality regardless of environmental stresses.

What Is the Lifespan of Bend-Insensitive Fiber Cables in Various Settings?

You’ll find bend-insensitive fiber cables typically last 20-30 years, depending on durability testing and material composition. In harsh environments, their lifespan may be shorter due to factors like temperature fluctuations and physical stress. Proper installation and protective coatings enhance durability, ensuring the fiber’s performance over time. Regular inspection and maintenance help you maximize the lifespan, making these cables a reliable choice for various settings.

Conclusion

By choosing bend-insensitive fiber cables, you guarantee your network stays reliable even in tight spaces. Imagine installing cables in a data center where space is limited—you can confidently bend them around obstacles without signal loss. This flexibility saves time and reduces costly repairs later. With proper handling and the right installation techniques, these fibers provide a durable, high-performing solution that keeps your system running smoothly for years to come.