Using cable carriers in industrial settings helps keep cables and hoses organized, protected, and safe from damage. Regular inspections guarantee they function properly and prevent unexpected failures that can disrupt operations. Choosing the right materials based on your environment and maintenance needs extends the lifespan of your carriers and improves system reliability. Thoughtful planning around durability, design, and upkeep can boost safety and reduce downtime. Stay tuned to discover how to select and maintain the best cable carriers for your needs.

Key Takeaways

- Regular inspections of cable carriers prevent wear, ensure proper function, and reduce unexpected system failures.

- Choose materials suited to the environment, such as corrosion-resistant options for harsh conditions.

- Opt for modular, smooth-surfaced carriers to simplify maintenance, cleaning, and quick repairs.

- Select carriers with adequate load capacity and durable materials to enhance longevity and system reliability.

- Plan maintenance schedules and material choices strategically to improve safety, reduce costs, and extend equipment lifespan.

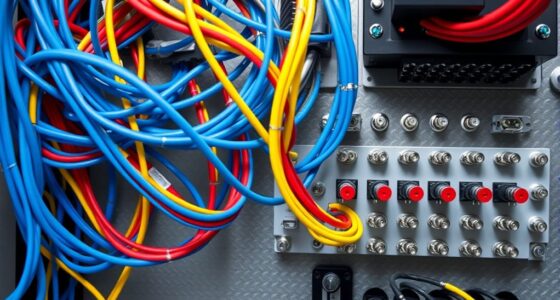

Cable carriers play a crucial role in industrial automation by protecting and guiding cables and hoses as machinery moves. When you’re implementing cable carriers in your facility, it’s imperative to establish proper maintenance schedules. Regular inspections help guarantee that the carriers are functioning correctly and prevent unexpected failures that could disrupt production. During these inspections, look for signs of wear, such as fraying or cracking, and check that the cables or hoses are neatly organized without excessive tension. Scheduling maintenance at consistent intervals allows you to catch issues early, reducing downtime and extending the lifespan of both the cable carriers and the cables they protect. Proper maintenance practices are essential for ensuring the longevity and reliability of your cable management system.

Material selection is equally significant when choosing cable carriers. You need to think about the environment and the specific demands of your application. For example, if your facility operates in a harsh environment with exposure to chemicals or extreme temperatures, you’ll want carriers made from durable, resistant materials like reinforced plastics or metals such as stainless steel. These materials can withstand corrosive elements and mechanical stresses better than standard plastics. On the other hand, for indoor applications with minimal exposure to damaging factors, lightweight and flexible plastic carriers may suffice, offering easier installation and cost savings. Your choice of material should also factor in the weight of the cables and hoses, as heavier loads require carriers with higher load capacities to prevent sagging or deformation over time.

When planning your material selection, don’t forget to think about the ease of maintenance. Some materials and carrier designs lend themselves to quicker inspections and simpler replacements. For example, modular carriers with snap-in sections allow you to replace damaged parts without removing the entire system, saving you time and effort. Additionally, selecting carriers with smooth surfaces minimizes the accumulation of dirt or debris, making routine cleaning easier and keeping your cables in good condition. This proactive approach to maintenance and thoughtful material selection keeps your cable management system reliable and efficient, minimizing the risk of cable damage or failure. Proper planning and material choice are vital for adapting to evolving industrial needs and ensuring ongoing operational safety.

Ultimately, your goal should be to create a system that combines durability, ease of maintenance, and adaptability to your specific industrial environment. By carefully planning maintenance schedules and choosing the right materials, you guarantee your cable carriers provide long-lasting protection and guidance for your cables and hoses. This not only enhances your equipment’s performance but also contributes to a safer and more productive workspace. In the end, investing time in these details pays off by reducing downtime, lowering maintenance costs, and maintaining smooth operations across your facility.

Frequently Asked Questions

What Materials Are Cable Carriers Typically Made From?

Cable carriers are typically made from durable materials like nylon, steel, or polyurethane. These materials offer excellent material durability, guaranteeing they withstand daily wear and tear. They also provide strong environmental resistance, protecting cables from dust, moisture, and chemicals. Depending on your specific needs, choosing the right material ensures your cable carriers last longer and perform reliably in demanding industrial environments.

How Do Cable Carriers Impact Overall Equipment Maintenance?

Sure, your equipment’s maintenance becomes a breeze with cable carriers, especially when you customize them to fit your needs. They keep cables organized, reducing wear and tear, which means fewer breakdowns and maintenance cost savings. Plus, tailored cable carrier customization means less downtime and hassle. So, you get a more reliable setup, saving you money and headaches—talk about a win-win in your industrial routine!

Are Cable Carriers Suitable for High-Temperature Industrial Environments?

Yes, cable carriers are suitable for high-temperature environments if they are designed with fire resistance and can handle thermal expansion. You should select carriers made from heat-resistant materials that prevent deformation and guarantee safety during extreme temperatures. By choosing the right cable carriers, you can maintain reliable operation, reduce downtime, and protect your equipment from heat-related damage. Always verify that the specific carrier model meets your high-temperature industrial standards.

What Are the Safety Considerations When Installing Cable Carriers?

When installing cable carriers, you should prioritize safety by securing them properly to prevent vibrations and noise from causing issues. Make certain they are supported correctly to mitigate vibration, which can lead to wear or failure. Check for proper alignment to reduce noise and avoid accidental snagging or damage. Always follow manufacturer guidelines, wear protective gear, and perform regular inspections to maintain safety and ideal operation.

How Do Cable Carriers Affect Cable Lifespan and Performance?

Cable carriers enhance cable lifespan and performance by maintaining cable flexibility and preventing unnecessary wear. They protect cables from environmental factors like dust, moisture, and mechanical damage, which could degrade performance over time. By organizing and guiding cables smoothly, cable carriers reduce strain and abrasion, ensuring cables stay flexible and functional longer. This combination of environmental protection and flexibility optimizes cable durability and maintains reliable operation in industrial settings.

Conclusion

Now that you know how cable carriers keep your operations running smoothly, imagine what could happen if one suddenly fails. Will your system be prepared? The right cable carrier isn’t just a choice—it’s a safeguard for your entire setup. Don’t wait until downtime strikes; explore your options today. The next move could make all the difference between seamless production and costly surprises. Are you ready to take that step before it’s too late?