It’s hard to overstate how vital proper cabling is in Industrial IoT environments—one mistake can disrupt entire operations. Balancing the need for reliable, high-speed wired connections with the flexibility of wireless options presents a complex challenge. From managing interference to ensuring scalability, your choices can make or break system performance. Understanding these cabling requirements is essential to building a resilient, efficient network that evolves with your needs. Here’s what you need to know.

Key Takeaways

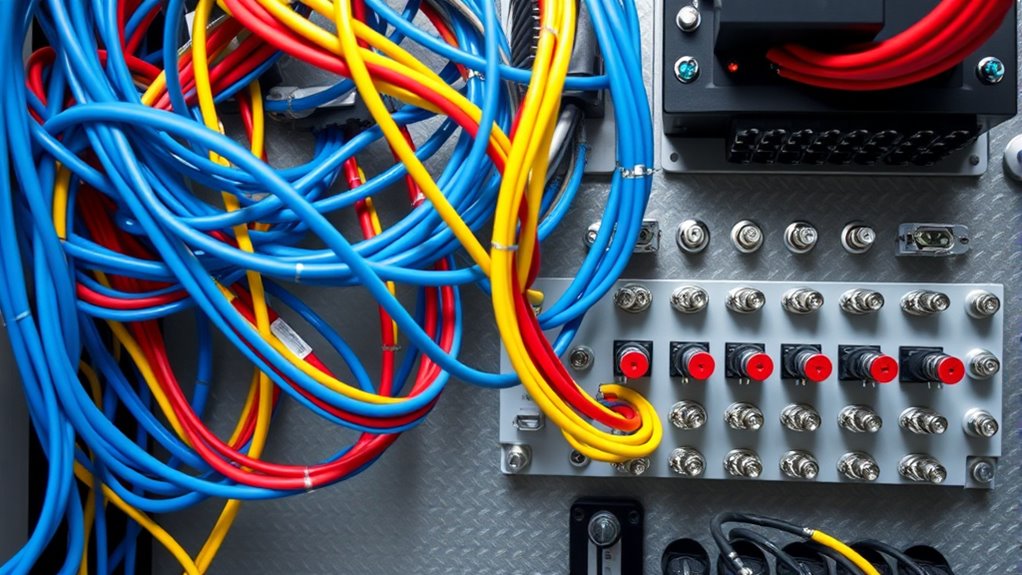

- Ensure robust cable management with proper routing, labeling, and separation of power and data cables to minimize interference.

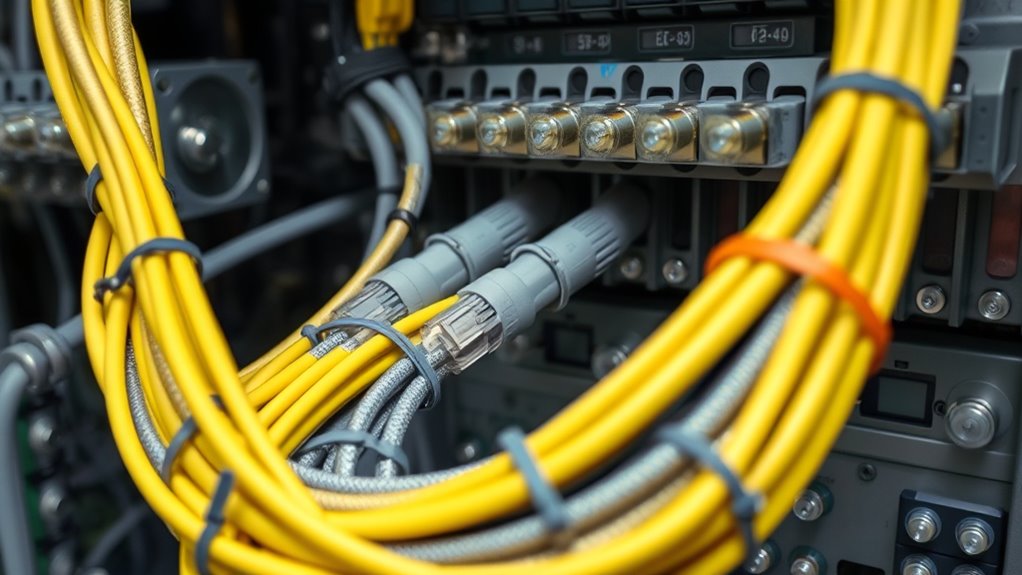

- Incorporate redundancy in cabling to maintain network connectivity during link failures or maintenance.

- Use durable, industrial-grade cables and connectors designed to withstand harsh environmental conditions.

- Document all cabling layouts and connections for troubleshooting, scalability, and future upgrades.

- Combine wired and wireless solutions strategically to balance reliability, flexibility, and network performance.

As Industrial IoT (IIoT) continues to transform manufacturing and automation, understanding cabling requirements becomes vital for ensuring reliable and efficient connectivity. While traditional wired connections have long been the backbone of industrial networks, you’re increasingly exploring wireless alternatives to reduce complexity and improve flexibility. Wireless options, such as Wi-Fi, Bluetooth, or emerging 5G solutions, can eliminate the need for extensive cabling in certain applications, especially where mobility and quick deployment matter. However, you need to carefully evaluate their reliability, security, and latency to determine if they meet your operational demands. Sometimes, a hybrid approach combining wired and wireless systems offers the best balance, providing robustness in critical areas while leveraging wireless for less demanding zones.

In your planning, cable management strategies play a vital role in maintaining system integrity and safety. Proper cable routing, labeling, and securing reduce clutter and prevent accidental disconnections or damage. You should consider using cable trays, conduits, and cable ties to keep cables organized and protected from environmental hazards like dust, moisture, or mechanical stress. Ensuring separation between power and data cables minimizes electromagnetic interference, which can cause data corruption or loss. As your network grows, implementing standardized cable management practices makes troubleshooting easier and enhances future scalability. Additionally, incorporating home decor principles such as aesthetic wall organization can help make cable management more visually appealing in shared or visible spaces.

While wireless alternatives provide flexibility, they also introduce challenges like signal interference, range limitations, and security vulnerabilities. To mitigate these issues, you might need to install signal repeaters or access points strategically, especially in large or complex factory layouts. Securing wireless communications with robust encryption protocols protects sensitive data from cyber threats. Additionally, maintaining a well-documented cable management plan helps you quickly identify issues when troubleshooting or upgrading your infrastructure. You should also consider redundancy in your cabling setup to guarantee continuous operation even if one link fails.

Ultimately, your goal is to create a resilient, scalable network that balances the advantages of wireless alternatives with the reliability of wired connections. Combining smart cable management strategies with thoughtful deployment of wireless technology enables you to optimize your industrial environment for both performance and safety. Staying proactive in planning and maintaining your cabling infrastructure will help you adapt to evolving IIoT requirements and keep your manufacturing processes running smoothly.

Frequently Asked Questions

How Does Cable Shielding Impact Industrial Iot Network Security?

Cable shielding enhances your industrial IoT network security by reducing electromagnetic interference, which can disrupt signal quality. When shielding is effective, it maintains signal integrity, preventing external signals from tampering or eavesdropping on your data. This protection minimizes vulnerabilities, ensuring your network remains reliable and secure. By choosing properly shielded cables, you safeguard your industrial operations from interference and potential security breaches.

What Are the Best Practices for Cable Management in Industrial Environments?

Did you know poor cable management can cause up to 30% more downtime? To optimize your setup, focus on cable organization by using color coding and proper labeling. Keep cables neatly routed and secured to prevent damage. Choose appropriate connector types for each application, ensuring compatibility and ease of maintenance. Regular inspections help identify wear and tear early. Good cable management boosts system reliability and simplifies troubleshooting, saving you time and money.

How Can Cable Durability Be Tested for Harsh Industrial Conditions?

You can test cable durability by subjecting them to environmental resistance tests like temperature cycling, humidity exposure, and chemical resistance. Also, assess cable flexibility by bending and twisting samples repeatedly to make certain they withstand movement without damage. These tests simulate harsh industrial conditions, helping you verify that cables maintain performance and integrity over time in challenging environments. Regular testing ensures your cables meet durability standards and reduce downtime risks.

What Standards Govern Industrial Iot Cabling Installation?

You should follow industry standards like ANSI/TIA-568, UL, and IEC for industrial IoT cabling installation. These standards guarantee your cabling meets safety, performance, and durability requirements. Always adhere to installation guidelines, such as proper cable routing, secure connections, and labeling. Compliance with these standards helps prevent failures, simplifies maintenance, and assures your system’s reliability in harsh industrial environments.

How Does Cable Selection Affect Data Transmission Speed and Reliability?

Your cable selection is the backbone of fast, reliable data transmission, like a highway for information. Using high-quality cable material and appropriate connector types reduces signal loss and interference, ensuring smooth data flow. If you choose sturdy cables with proper shielding, you boost speed and dependability. Conversely, cheap or incompatible connectors cause delays and errors. So, pick wisely, because your network’s performance depends on the right wiring choices.

Conclusion

By balancing wired and wireless solutions, you create a network as reliable as a well-oiled machine. Proper cable management, redundancy, and thorough documentation guarantee your system stays resilient and scalable. Think of it like a well-organized toolbox—everything’s in its place, ready when you need it. This hybrid approach not only boosts operational efficiency but also keeps your industrial IoT setup flexible and secure for whatever the future holds.