While traditional maintenance relies on reactive fixes after failures, predictive maintenance offers a proactive approach that could transform how you manage cabling systems. By continuously monitoring cable health through sensors, you can detect issues early and prevent costly downtime. But implementing such technology raises important questions about accuracy, cost, and integration—topics worth exploring to see if this strategy is right for your operations.

Key Takeaways

- Sensor integration enables real-time monitoring of cable health parameters like temperature and vibration.

- Automated alerts facilitate quick responses to emerging cable issues, reducing failure risks.

- Predictive maintenance extends cable lifespan by addressing problems before failure occurs.

- Data-driven insights optimize maintenance scheduling, lowering costs and minimizing downtime.

- Overall, it shifts maintenance from reactive to proactive, enhancing system reliability and operational efficiency.

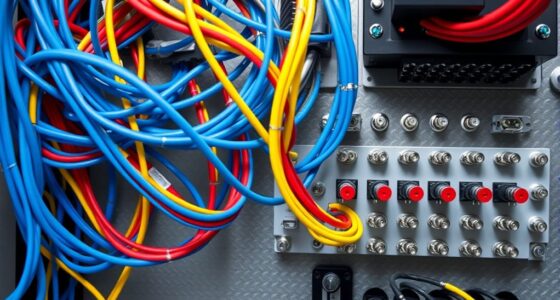

Have you ever wondered how predictive maintenance can revolutionize the way you manage cabling systems? It’s a game-changer, especially when you leverage sensor integration. With sensors embedded in your cabling infrastructure, you gain real-time insights into the health of your cables. These sensors monitor parameters like temperature, vibration, and electrical resistance, providing immediate feedback if something’s amiss. Instead of waiting for a failure or inspecting cables manually, you get continuous data that helps you stay ahead of potential issues. This proactive approach allows you to plan maintenance more effectively, avoiding unexpected outages and costly repairs.

Sensor integration streamlines maintenance scheduling by offering precise, data-driven insights. When sensors detect anomalies, such as overheating or unusual vibrations, you can schedule maintenance exactly when it’s needed—not too early, not too late. This targeted scheduling reduces unnecessary inspections and minimizes downtime. You no longer have to rely on routine checks that might be inefficient or too infrequent. Instead, you develop a maintenance schedule based on actual cable conditions, which enhances reliability and extends the lifespan of your cabling infrastructure. Plus, because you’re responding to real-time data, you can prioritize repairs, focusing resources where they’re most needed.

Implementing sensor integration also improves your overall maintenance workflow. Automated alerts can notify you immediately when a sensor detects an abnormal reading, allowing for swift action. This reduces the risk of minor issues escalating into major failures, which could disrupt your operations considerably. Maintenance becomes more precise, less reactive, and more aligned with the actual condition of your cabling system. As a result, you save money on unnecessary repairs and avoid the costs associated with unplanned downtime. Additionally, this approach provides valuable historical data, helping you analyze trends over time and refine your maintenance strategies further.

In essence, the combination of sensor integration and smart maintenance scheduling transforms your cabling management. It shifts you from a reactive mindset to a proactive one, where issues are addressed before they cause disruption. With real-time data, you gain better control over your infrastructure, ensuring higher reliability and efficiency. You’ll find that maintenance becomes less disruptive, more cost-effective, and easier to plan. Embracing predictive maintenance with sensor integration not only minimizes risks but also maximizes your system’s performance. It’s about working smarter, not harder, and ensuring your cabling infrastructure remains resilient and dependable for the long haul.

Moreover, understanding preventative maintenance concepts can further enhance system longevity and reduce unexpected failures.

Frequently Asked Questions

How Does Predictive Maintenance Impact Overall Cabling Infrastructure Costs?

Predictive maintenance helps you reduce overall cabling infrastructure costs by preventing unexpected failures and minimizing downtime. By regularly monitoring your cabling system, you can identify issues early, leading to cost reduction in repairs and replacements. This proactive approach also boosts system reliability, ensuring your network runs smoothly. Over time, these savings and improved reliability profoundly lower long-term infrastructure expenses, making your cabling investment more efficient and resilient.

What Are the Best Sensors for Predictive Cable Fault Detection?

A stitch in time saves nine, and choosing the right sensors is key. You should prioritize fiber optic sensors for their high sensor accuracy, especially in detecting subtle faults early. Pair these with advanced fault detection algorithms that analyze data precisely. This combination enhances early fault detection, minimizes downtime, and extends cable lifespan, making your infrastructure more reliable and cost-effective.

How Often Should Cabling Be Monitored for Predictive Maintenance?

You should monitor your cabling regularly, ideally based on its cable lifespan and usage conditions. For critical systems, check at least quarterly, but for less essential setups, biannual assessments may suffice. Consistent monitoring helps optimize maintenance scheduling, catching issues early before failures occur. Keep track of cable performance data to adjust the frequency as needed, ensuring your cables stay reliable and avoiding costly downtime.

What Role Does AI Play in Predictive Cabling Maintenance?

AI plays a vital role in predictive cabling maintenance by enabling AI-driven diagnostics and real-time data analysis. You can rely on AI systems to continuously monitor cabling conditions, quickly identifying potential issues before they escalate. This proactive approach helps you reduce downtime and maintenance costs, ensuring your infrastructure stays reliable. By analyzing data in real-time, AI empowers you to make informed decisions and maintain peak cable performance.

Are There Specific Cable Types Suited for Predictive Maintenance Systems?

Think of cable types as the backbone of your system, like sturdy bones supporting your body. For predictive maintenance, you want cables with excellent insulation and connector durability, such as shielded twisted pairs or armored cables. These types resist wear and signal interference, ensuring reliable data flow. Choosing the right cables helps you catch potential issues early, preventing costly failures and keeping your system running smoothly.

Conclusion

By embracing predictive maintenance for cabling, you’re not just preventing failures—you’re rewriting the future of your infrastructure. Imagine having a crystal ball that warns you of issues before they happen; that’s what real-time sensor data provides. With proactive care, you’ll reduce costs, extend cable life, and keep systems running smoothly. Don’t wait for disaster to strike—turn insights into action and make reliability your new standard. After all, foresight is the best form of insurance.